The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Outdoor

- >

- How to make an automatic rotated seedlin...

How to make an automatic rotated seedling planting system?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to make an automatic rotated seedling planting system?

Hi Team,

I am Ashriya and you might already know from my previous posts - making a seedling planting system. I have came up with another idea.

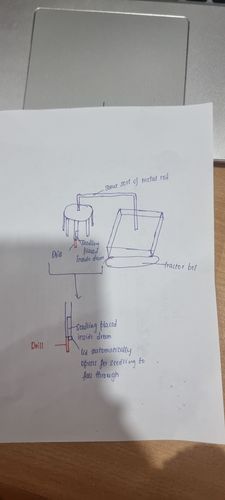

uhm imagine a metal rod, holding the entire cylinder drum bit like a pendulum but rather steady in terms of horizontal motion but goes down and up to its original spot. the cylinder bit will rotate as its got a 6 drums for now, which have a drill attached to the end of it, and has a seedling inside the drum and has a small lid opener right underneath it, so it uses some kind of sensors to when the metal rod pushes the cylinder bit to go down and drill into the soil and come back up, using sensors it will open the lid for the seedling to fall through and it rotates after that.

Is there any advice on what kind of materials and how I can get started on this project?

Few questions I am also currently considering for this system is

1. how will the seedlings be watered?

2. how will the seedling fall straight down once the lid is open?(as there is no pvc pipe for the seedling to fall through)

3. how can i make this system automatic?

Your help would be greatly appreciated!!!

Thank you

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to make an automatic rotated seedling planting system?

Hi @ashriyavarri,

It's good to have you back with new ideas for your planting system.

I would suggest getting a clear idea of the structure of your planter before delving too deeply into the nitty gritty of making it work. Oftentimes, just getting a start will help to clarify where you are going with things.

I would look at Australian Handyman Supplies 20 x 20 x 1.6mm x 2.16m Painted Square Hollow Section Steel as an option for building the frame of your system. You could then use Easyroll 2.5 x 4" Nylon Trolley Wheel With 3/4" Axle Diameter as the wheels.

I am a very visual person who likes to be able to check things out from all angles. Once you have the frame made, you might find that some of your ideas work in theory, but they might not with the frame you've constructed, but it will certainly help to clarify what is and isn't possible and allow you to ask the specific questions that you'll need to answer to turn your vision into reality.

Allow me to tag some of our helpful members to see if they can offer any ideas on your updated project: @CSParnell, @Nailbag, @Noyade, @Dave-1.

Feel free to reach out with any further questions.

Jacob

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to make an automatic rotated seedling planting system?

Hi @ashriyavarri again.

On another thread you mentioned you had less than four months to build this machine. You told me it had to be full scale, I think, and expected to be a functioning prototype which had to be assessed on how well it met the criteria?

What strikes me as odd is you said your teachers told you "to go to Bunnings" which to me is fine, but looking at some of your designs an engineering firm/supplier looks more likely. Your latest napkin design, to me, appears to require electric motors, solenoids, hydraulics, large augers and bottom right - a transportation system employing engine/transmission caterpillar tracks?

Would it be worth going back to your teacher/s and showing them your designs and clarifying exactly what is required of you? I'm with @JacobZ in that Bunnings could/can supply many materials to make something that would help you construct, say a 1/5 scale articulating model that explains your design.

What do you think? Have you seen some of the complexity in making the tracks for instance?

This is jaw-dropping....

Please keep us informed. I'm genuinely interested.

Cheers.

Graeme.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to make an automatic rotated seedling planting system?

Hi @Noyade,

No, I have 4 months left to make this project. The entire purpose of this project is to find a problem and make an innovation/solution and I have to make this system working so not exactly a prototype but I will developing a prototype and working on from there, which is exactly why I'm considered a small sized system from the very start and having a look at the video - I like the idea but I believe its a little too big and heavy.

Please have a look at the following video, the weight is something I'm hoping for my system similar to the one shown in the video.

Do you also have any recommendations on who I could possibly contact?

https://youtu.be/sKRBHaOkXlo?si=t9pNekgWGHrvrWs6

Thank you!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to make an automatic rotated seedling planting system?

Hi @Noyade

I have asked one of my friends to create an explanation of my system in terms of lego pieces in a video. https://drive.google.com/file/d/1RqqA-TUns8QmhfDv1XtCGSOLAMMCZB5m/view?usp=drive_link .Please feel free to have a look at the video and understand the process. My only concern right now, is I don't know how I make that mechanism in real life. Could you please assist me from scratch in terms of materials to be used and how and where exactly i can put the one dc motor in place for the entire system to work? In terms of the auger, I have watched a diy auger video and thinking of making exactly that - https://youtu.be/RL7UEei-ck8?si=EXDCj6jVGyLLSfps

Thank you

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to make an automatic rotated seedling planting system?

Morning @ashriyavarri

"Do you also have any recommendations on who I could possibly contact?"

I was gonna suggest places like TAFE and Men's Sheds and even Metalworking forums. There is a good one which is connected to the Australian Woodworking Forum and some of moderators there are TAFE welding lecturers - but be warned, some members can be brutal with their comments and criticisms.

But having seen that video! I'd be trying to talk to those involved at the University of Victoria . But would they talk? Is the machine heading to the patent office?

The seedling delivery is simply magic. It even addresses the problem of "dead space" which I think your auger method would be likely to do, with what looks like a mechanical hand that pushes the earth back. I think that would be essential? It looks to be powered by batteries and is there a compressed air tank at the back?

Plus your rotating chandelier above requires six or more augers? And every time you retract the auger - the head must accurately (in fact, precisely) move a set number of degrees for an accurate deposit of the seedling?

Your thoughts?

Cheers!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to make an automatic rotated seedling planting system?

"In terms of the auger, I have watched a diy auger video and thinking of making exactly that"

Looks interesting. Please show photos when completed.

Cheers!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to make an automatic rotated seedling planting system?

Ho @Noyade,

After looking at the video, do you have any ideas on how exactly i can power the Geneva drive using the axle rotation. As there was a problem with every rotation of the axle, its going to cause the drum to release a seedling. Hence, I've had to gear down in which using a small gear for the drive wheel and larger gear for the geneva drive. In terms of materials, I'm thinking of a very small sized system using plastic materials that showcases a working model of a real one. However, if you have any ideas for the materials for the entirety of that system showcased in the video, please let me know as I'd be more than happy to get started.

Thank you.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to make an automatic rotated seedling planting system?

Hey there @ashriyavarri

"do you have any ideas on how exactly i can power the Geneva drive using the axle rotation"

Do you mean at a Bunnings level or a University of Victoria level?

I certainly can't do the latter.

And I had to look up Geneva Drive - (I was thinking Colditz).

I'm cooking a curry at the moment (plus a glass of red) and all I can think of is a right-angle driver (with the chuck removed) connected to, believe it or not - a battery powered drill on low gear?

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.