I built a deck that sat flush with my back door, a task made difficult with a clearance of only around 150mm from step to ground. Here is how i did it.

Materials

- 10mm Dynabolts (galvanised)

- 10mm Coach Screws (galvanised)

- 10mm Hex Bolts (galvanised)

- 100 x 100 x 105mm M10 Galvanised Angle Bracket

- 200*45 Treated Pine (doubled for frame)

- 90*45 Treated Pine (joists)

- Pryda Half Stirrups

- Pryda Nails (for Joist Hangers)

- Pryda Joist Hangers

- Macsim 8G Deck Screws + Macsim Clever Tool (highly recommend)

- 90mm Merbau

- 35-40 bags of concrete

- G-Tape and Protectadeck timber protection tapes

- Deck Spacers

Total Cost ~$4,500

Before

After

Preparation

- Removed existing porch cover and cut down tree

- Excavated an additional ~200mm of soil, giving myself ~350mm of total clearance

Drainage

- Dug trenches and installed a french drain, plumbed into an existing storm water connection (lucky)

- Geo textile fabric helps keep the slots on the Agi Pipe unclogged with dirt

- A thin layer of Scoria between Geo textile fabric and Agi Pipe also assists in keeping the dirt out

Ledger Board installed

- Sets the height of the whole deck (deduct the height of the deck boards!)

- 10mm Dynabolts were a bit overkill

- Be sure to have already marked where the joist hangers will be so that the bolts don't get in the way

Frame

- 200*45 Timber for frame. Double thickness (200*90) and joined using timber glue and Batten Screws

- Dig the holes for the posts/stirrups

- Dropped the bearers into place and screw together using Galvanised Angle Brackets

- Using three Car Jacks, carefully adjust the frame so that it's perfectly level and flush with the ledger board

- Screw the Stirrups onto the Bearers so that they 'hang' above the post holes using coach screws

- Screw the frame to the ledger board using coach screws

- Fill the Holes with concrete and leave to set (make sure the concrete has a slight dome shape to allow water run-off)

Joists

- Use string line to mark the position of the Joist Hangers

- The joist hanger nails are much cheaper than the screws. You must use the special nails/screws from Pryda

- Clamping the joist hanger onto the joist with a C-Clamp made it a bit easier

- I used 12 nails per joist hanger

Decking

- Important: Run a belt sander across uneven areas of the deck frame, smoothing them so there won't be any unevenness when walking on the deck

- If exposed to the elements, use G-Tape and Protectadeck on the frame for protection (Took approx 30 minutes with a staple gun)

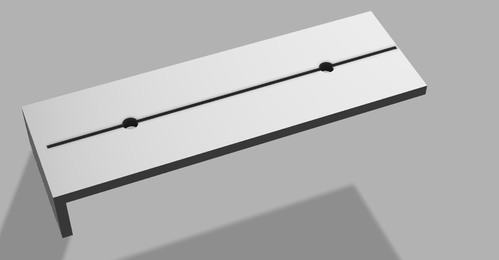

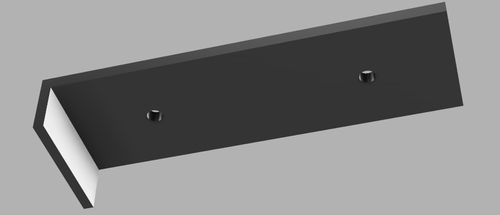

- 3D printed a jig for guiding placement of deck screws

- Use Car Jacks to press warped deck boards against deck spacers (see pic)

Decking Board Installation

- Best done as 2 person job

Person 1

- Use centreline of Jig to place directly under string line

- Predrill pilot hole

- Remove Jig and use Clever Tool to drill and countersink hole

Person 2

Completion

- Carefully trim the excess off the Merbau by running a Circular Saw across either end (I used a clamped piece of timber as a guide)