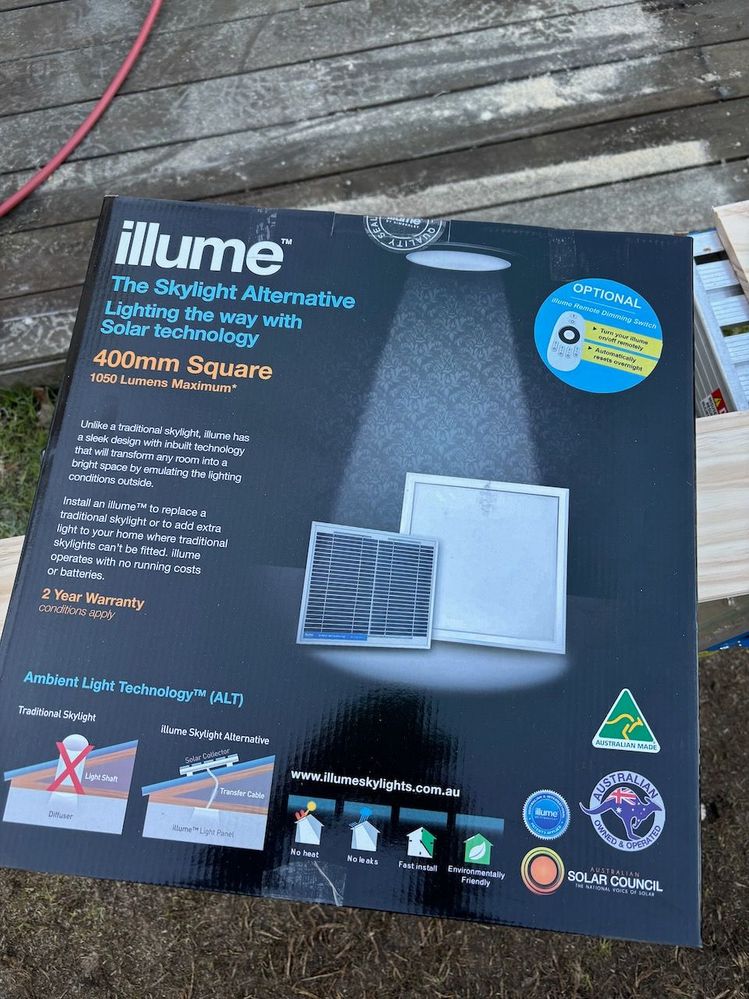

This kitchen dining area suffered from poor natural light as all the windows face south and being the lower level of a 2-storey 1950's coastal home. Traditional solar-tube skylight wasn't going to work, but I heard from a friend who had installed solar-powered sky light from illuma that Bunnings range. They work on an ambient light sensor in the solar panel that increases the brightness automatically based upon the ambient outside light. Brighter the day, the brighter the LED skylight.

Here's how it was installed.

Steps

Step 1

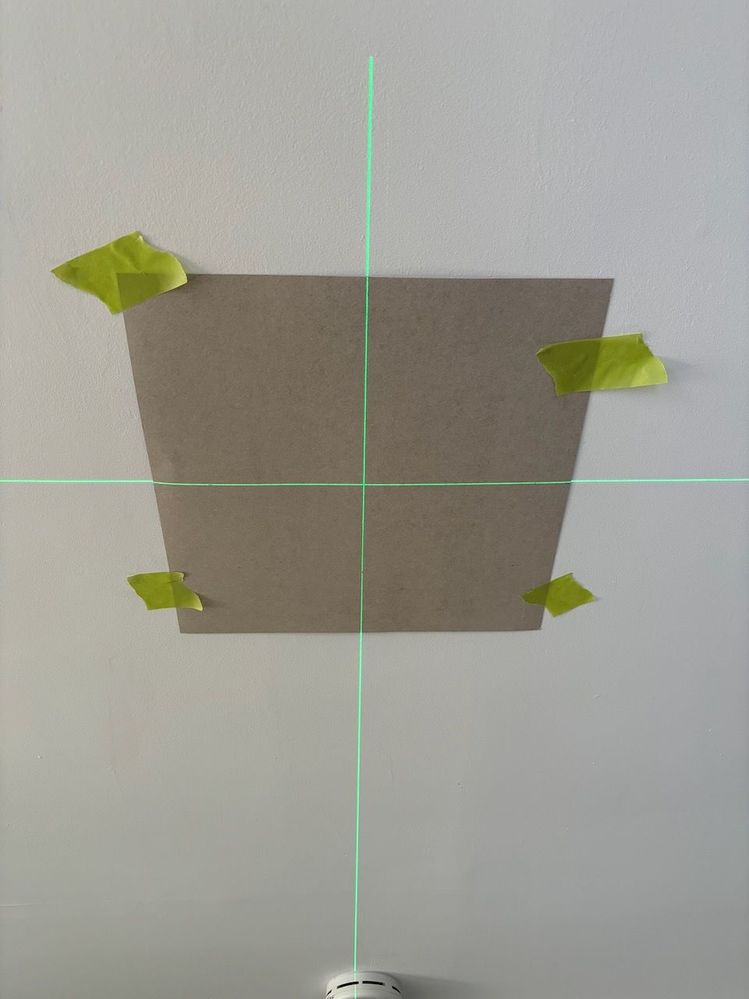

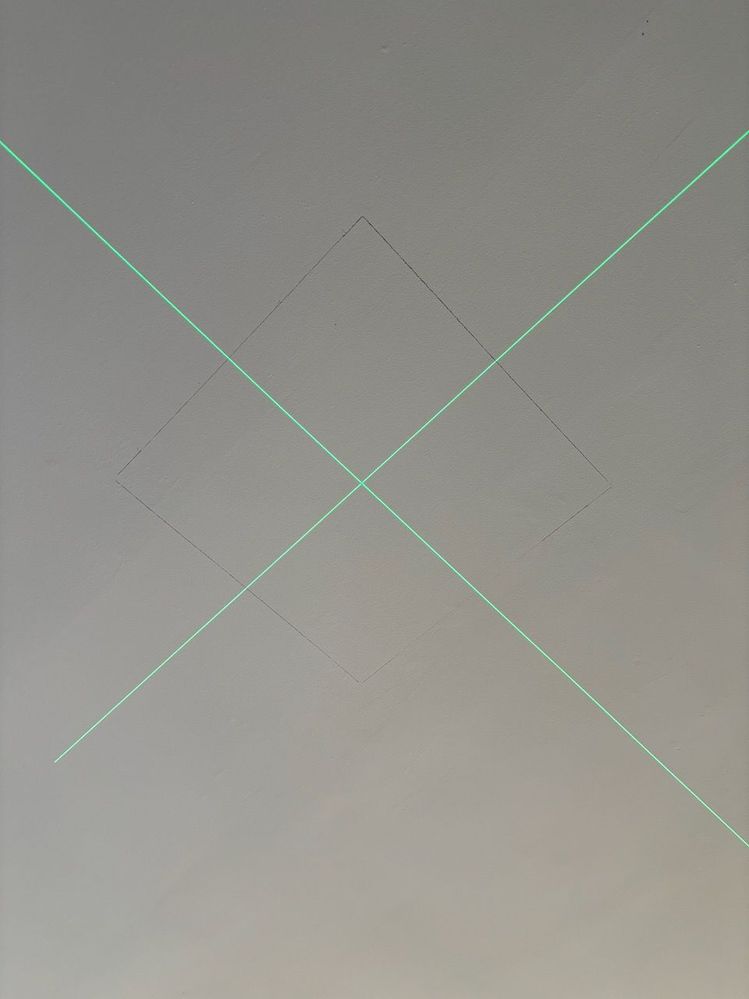

The first step was to find the centre of the room which I marked with a 360deg laser. But a tape measure works just as well, it simply takes longer.

The important part is to ensure that the light panel was going to fit square/parallel to the room.

Step 2

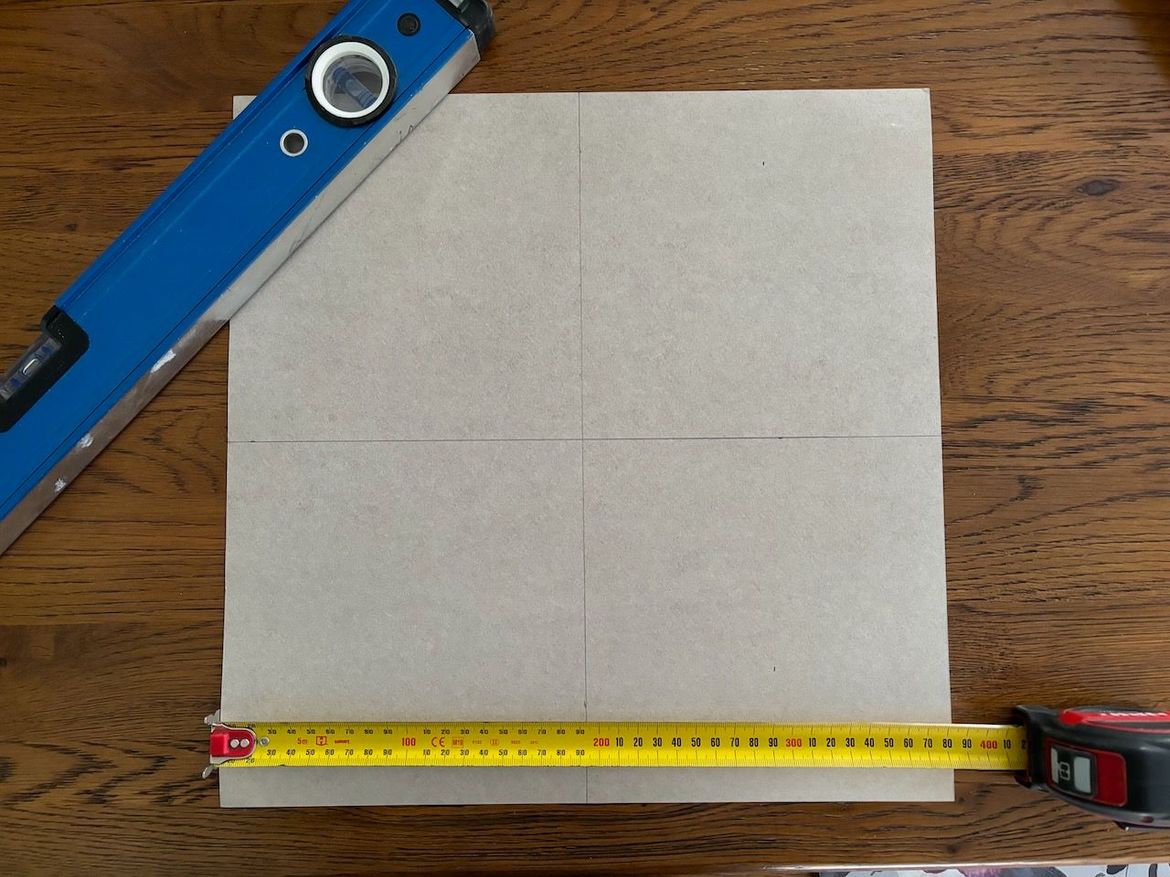

I then marked the centre of the cutout template and taped it to the ceiling in alignment with my laser lines. Then marked the cutout.

Step 3

I used a plasterboard jab saw to make shallow cuts, and typical of my luck found not one, but two joists. So I used a multitool to finish the cut out.

With the cutout removed, I needed to then check out both joists with a hammer and chisel to allow for clearance of the panel and its fixture system

Step 4

I used a length of yellow tongue to run the power cable from the solar panel, connected the control module and then taped the connection and fitted the skylight panel and gave it a quick test that it works before mounting the solar panel.

The spring clips on the panel are very strong, and more so than those found with LED downlight, so watch your fingers!!!

Step 5

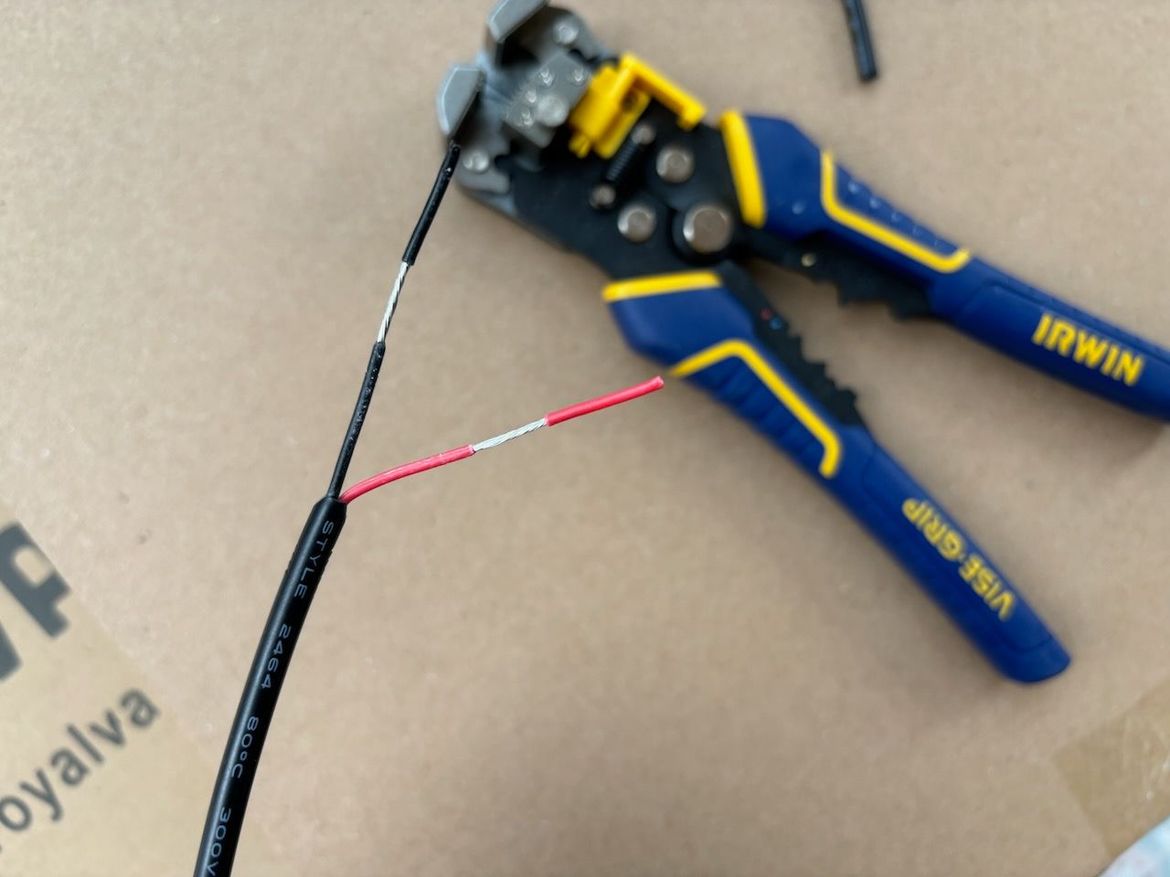

I only had a very narrow space to feed the cable through the ceiling cavity and out through a colourbond roof. It meant having to cut the cable as the power plug was too large.

The cable was fed through a rubber grommet to protect it from the sharp edges, and then siliconed for waterproofing

Step 6

The solar panel mounting brackets require you to cut them to suit the mounting type. I then fitted them to the elongated slots so I could adjust them to fit to the high-side of the corrugated roof profile.

Step 7

Once on the roof I marked out the mounting holes and applied a generous amount of roof and gutter silicone before fixing the panel with self-drilling hex screws. Then I applied more silicone.

Step 8

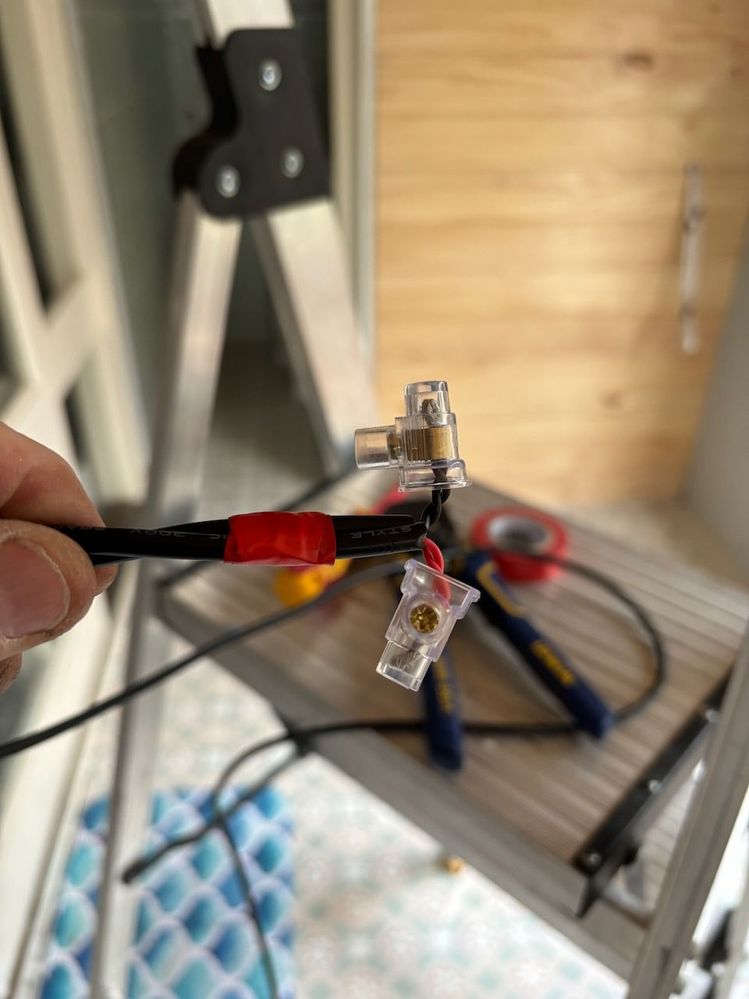

The last step was to splice and join the cut power cable.

Step 9

Job done 👍