Steps

Step 1

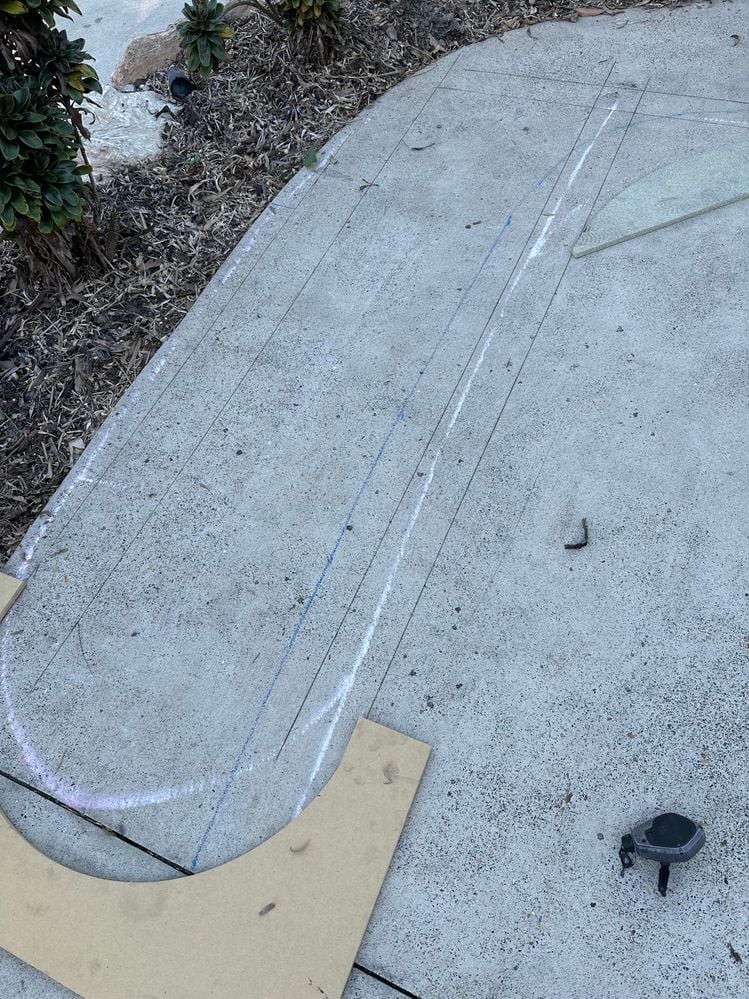

Marking out the bench seat:

We began by carefully marking out the shape and dimensions of the bench seat using a chalk line, tape measure, pre made templates and builders crayon. This helped ensure consistency and accuracy throughout the design.

Step 2

Pre drilling for reinforcement bars:

Once the layout was marked we drilled all the necessary holes into the existing concrete slab at the marked points. These holes were carefully positioned to securely hold the bars and align with the final seat shape.

Step 3

Chemical fixing of reinforcement bars:

The reinforcement bars were chemically set into the pre drilled holes. This ensured the bars were firmly anchored into the slab to provide stability and strength for the seat.

Next we began shaping all the bars for the frame using a bar cutter bender and rod ties.

Step 4

Building the curve formwork shapes:

We used MDF templated to map out and form our custom curves. Once the curves were shaped we nailed them together to hold their form.

The entire structure was then reinforced using pine timber studs, adding the strength and stability needed to keep the curves secure. Once complete, the formwork was put into place on the seat structure.

Step 5

Installing the rest of the formwork:

We created and cut out the shapes for the boxed formwork. The formwork was designed to securely contain the concrete, helping to prevent leaks or weak points that could lead to cracking.

To stabilise the structure we anchored the timber pine studs into the ground and positioned them to lean firmly against the formwork. This bracing system help everything in place and ensured the formwork remained strong and supported during the concrete pour.

Step 6

Concrete Pour:

We mixed the concrete by hand in manageable batches. making sure to achieve a consistent workable texture. Once ready, we carefully poured the concrete into the box formwork. Taking our time to fill every section evenly along the curved shape.

After the pour, we used a concrete vibrator and hand tapped along the formwork to remove any air pockets and help the mix settle properly. This step was crucial to achieve a dense, solid finish without internal voids. Reducing the risk of future cracking or structural issues.

Step 7

Concrete unboxing:

After allowing the concrete seat to cure for 24 hours we began unboxing . First we removed all the timber bracing and then carefully began to remove each piece of formwork so we did not disturb or damage the freshly set concrete.

Step 8

Touched up concrete:

We then touched up the concrete where there were very slight external air bubbles. This was done so we would have a nicer finish when rendered.

Step 9

Hebel install:

With the concrete fully set & unboxed we moved on to installing the hebel onto the seating. To do this we first built a water resistant frame inside the concrete voids. This was so we were able to have support for the hebel and also fixing points for screwing the hebel. Making sure the initial frame was levelled before we installed the hebel.

Step 10

Render & paint works:

We then prepared the render by mixing it as per the instructions on the bag. Making sure it was lump free. Once the first coat began to firm up we used a float to smooth it out and create a uniform finish.

Once the render was fully cured over a few weeks, we then painted the seat in a UV outdoor paint. We applied 2 coats of paint