Steps

Step 1

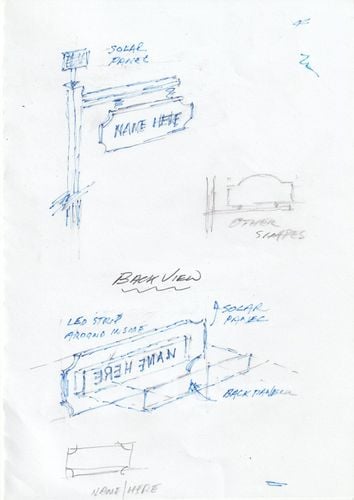

As always started with a sketch to transfer thoughts to paper.

We need a cutting template - quite a large one!

I have a A3 printer and it will be two landscape sheets lined up and sticky taped in the middle.

Created the template in MS Word which will be stuck onto the workpiece.

Timber is expensive... dressed pine and marine ply is expensive so wherever possible I use fence palings.

I run them through the planer thicknesser.

They come out like this... nott bad er.

One example, another storage unit made from fence palings.

We need to stick the template onto the workpiece and here I have a tip. Firsty lay down masking tape, do the spray adhesive thing and then align and stick down the template. Later on the template easily pulls of.

Ready to move over to the scroll saw.

And off we go... this part can be quite stressful.

With the pilot holes done we just completed the 'O' letter. Internal cutting is time consuming and unmounting/mounting the blade can be frustrating. I use an open safety pin which which provides a better view of the upper arm slot because the hand is towards the right. The 'O' required two changes, that letter on the right requires four changes!

Looks like this.

Moving along to the left.

Nearly there... phew.

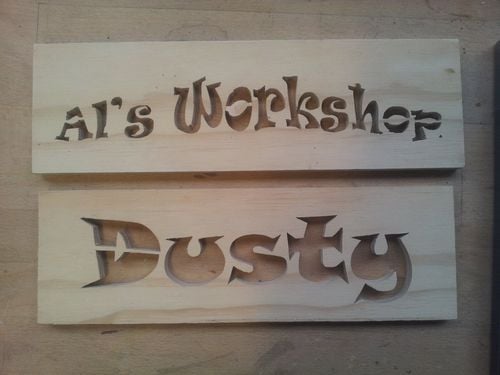

With the letters done time to clean up all the segments.

Stage 1 completed.

Step 2

Making a frame that will be glued and tacked onto the back of the sign. The strips of timber I am using are from a carton of ALDI garden stakes, very handy for woodworking.

Was going to use the Ozito stapler/bradder but the brad's are too long - used flathead brad nails.

The back panel will be secured with screws.

Like this.

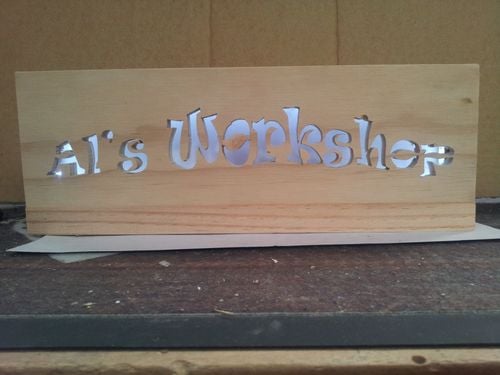

Starting to take shape... looks OK.

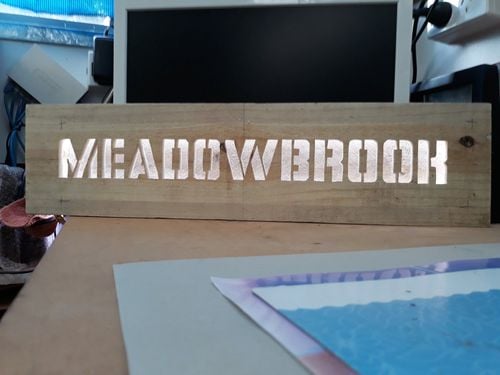

At this point I'm wondering what it will look like illuminated after dark so let's do a lighting mock-up

I ran LED strip lights around the inside held down with sticky tape. Late afternoon so using some cardboard to block out light from the the two back workshop windows.

Leave it here and come back later.

Looks good.

At this point I installed the LED strip in the usual way, peel of the backing and stick down. With outdoor weather conditions in mind I also spot glued the strip with a hot glue gun.

Out in the backyard I powered up the lights with a power bank.

Happy with that.

Step 3

Here's the setup I am using.

Time for some spray painting.

Everything pulled apart to prep for spray spraying.

I use a lazy susan for spray painting, slowly rotate for even spray application.

Solar LED strip lighting - Search 'solar led strip lights outdoor' and you will likely end up with a headache sorting through what's on offer.

You can also use the same build procedure to make other stuff.

Name plaque for our beloved Golden Retriever when she crossed the bridge @ age fifteen plus.

That's all folks...