A 1:2 scale timber billy cart built from plans for a 1952 Morgan motor car.

The project

I started this project when I saw a post about US cycle carts. As I have twin grandsons, I thought that I could build them the billy cart that I always wanted. One day when walking through my local Bunnings in Hawthorn, I spotted four wheels that would be the perfect size and axles to suit. With these in hand I had no choice but to begin.

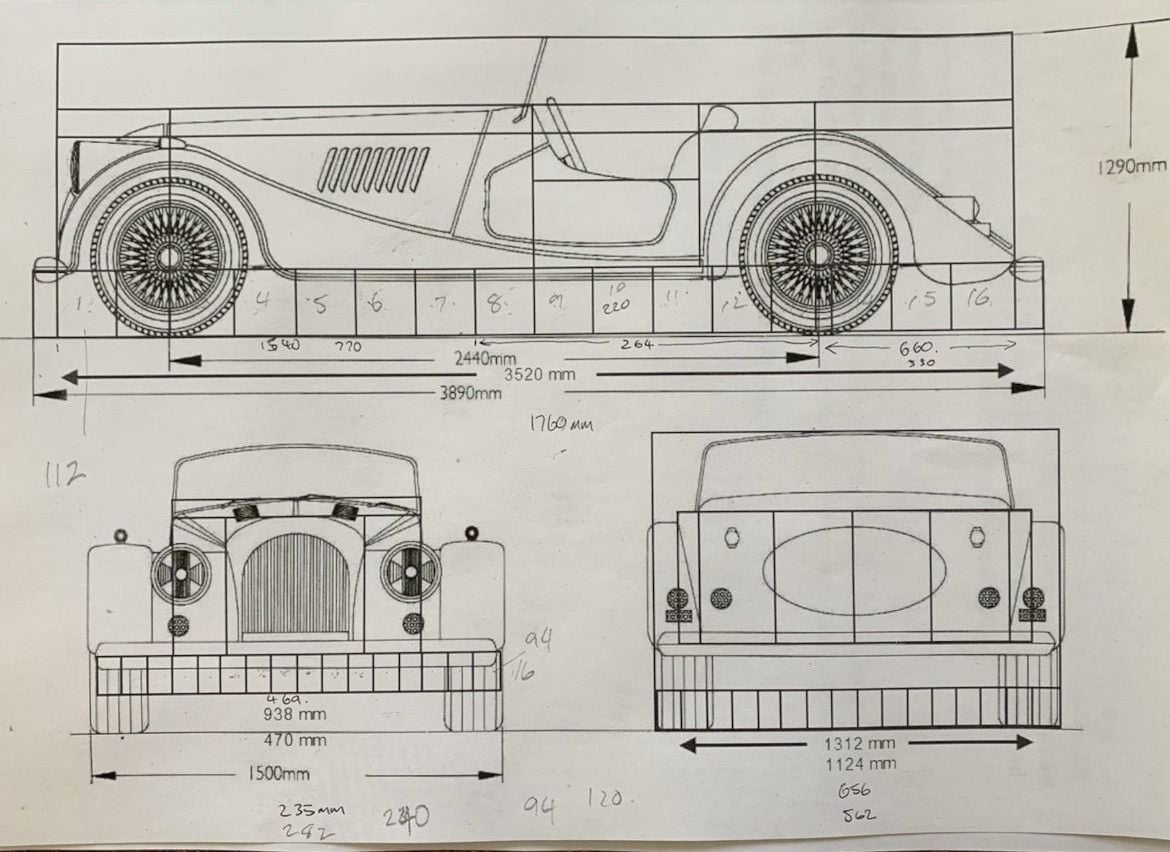

I love Morgan cars and as they are largely built with timber frames I decided to create a 1:2 scale of a 1952 Morgan. Here is a copy of the plans I used based upon the Morgan UK website.

This was a long way from my first build.

With these plans in hand, I popped back to Bunnings to buy materials and some new Ryobi tools. Many hours and trips later, learning new skills such as welding, timber bending and upholstery, the cart hit the road.

The brakes are hydraulic from an old mountain bike. They required specific mounts each side as the calipers on the left had to be reversed.

In order to get the brakes activated by one pedal, I created a linking box, one line in from the brake pedal with a line out to each brake caliper.

This picture is upside down and it shows the adjustable motor mount.

Chain drive to axle through pillow blocks.

The hydraulic brake pedal.

The motor is from an electric golf buggy powered by a rechargeable mobile scooter battery. There is a second battery in the front for the head and tail lights. All electrics are controlled by a switch panel on the dashboard with a speed controller on the left.

The base of the grille is made of a few pieces of hardwood that were handcrafted into the desired shape. I then made the front flat piece from two sheets of 4mm aluminium, made a paper template of the shape of the grille, cut it out of 1mm aluminium and using a Soft Headed Hammer beat the aluminium to the shape of the grille. The badge was 3D printed by a friend and will be redone as we have access to a far better printer now. The headlights are from a Harley and the rears from a Triumph. Both work from switches on the dashboard.

Having a foot throttle was too hard as my grandsons' feet could not reach. The bolt on the left of the motor sets the tension on the chain drive. The wheels are locked in place on the axle but can be set to free roll as well. The axle runs through two pillow bearings. The steering box is an old Stanley hand drill, the universals and tie rods all came from RS Components in Sydney. They have a huge range of stuff for many projects, mainly specialised, that I have not found anywhere else.

The steering wheel was also made from a 6mm sheet of aluminium as was the windscreen frame. Perhaps the hardest part was cutting the perspex front screen to perfectly fit the frame. The first attempt had a few cracks but the second is perfect.

This year we are taking it to the Red Bull Billy Cart Race in Melbourne - not to run down the hill jumps but in the build competition.