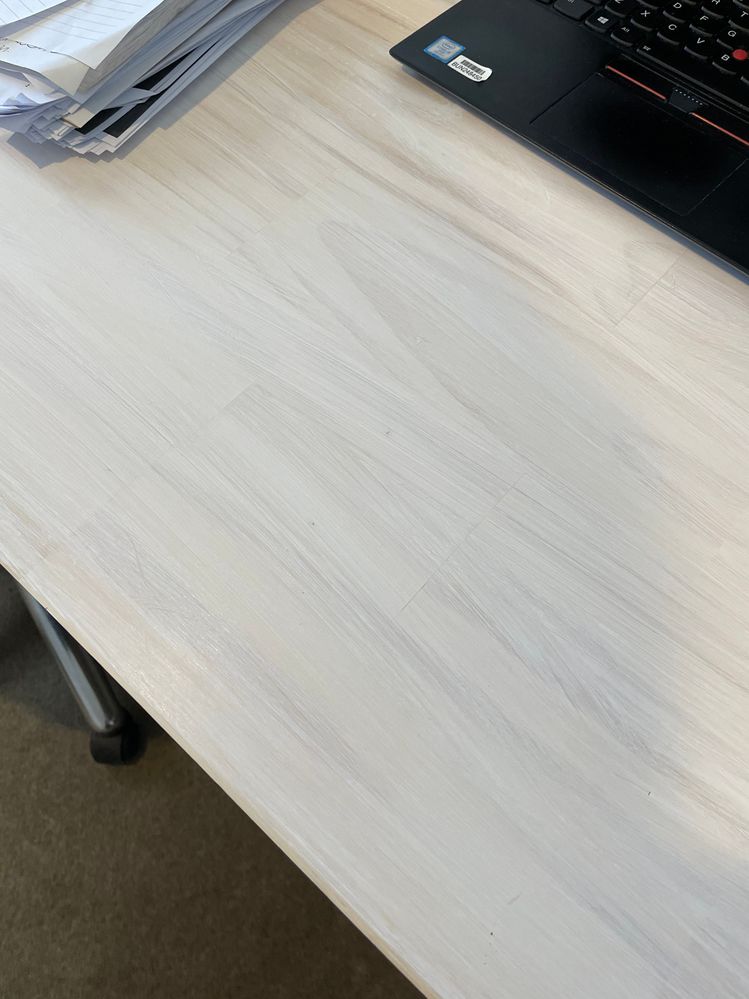

This easy D.I.Y. desk utilised RapidMesh furniture legs and a Pine panel.

The project

In need of a new desk, I had two RapidMesh furniture legs and a Pine panel delivered during lockdown.

We painted the panel with liming white paint and it came up really well.

The liming wash was great to use and it's a more subtle white than a white gloss. I only used one coat of the liming wash as I still wanted to see the grain of the timber. It was easy to apply and I left it to dry overnight before I added the desk legs.

I used six screws to secure each leg. The holes are already in the legs so it's easy and solid.

Materials

- 2 RapidMesh 70 x 73.2 x 6cm Black Santos steel tube table furniture legs

Popular desk projects

Creating a dedicated workspace or updating an existing one can be simple and affordable, and you'll have everything you need to be more productive when working from home. For more simple D.I.Y. desk projects, check out our Top 10 most popular desk projects.

This simple and spacious deck by robchin should also provide inspiration.