We purchased the home in November 2022. The cement render around the garage door an front entry had substantial damage an the paint was faded an stained. The blueboard above the garage door had cracked on every joint. The other consideration was as the home faced west with a wide streetscape, the amount of heat entering the home from the western sun needed to be addressed. We already had ceiling insulation an a solar extractor, so sun screens were an option to deflect the heat from the brickwork. After a few weeks of planning an several visits to our local Bunnings, the project was underway.

Home when purchased.

Home when purchased.

Materials

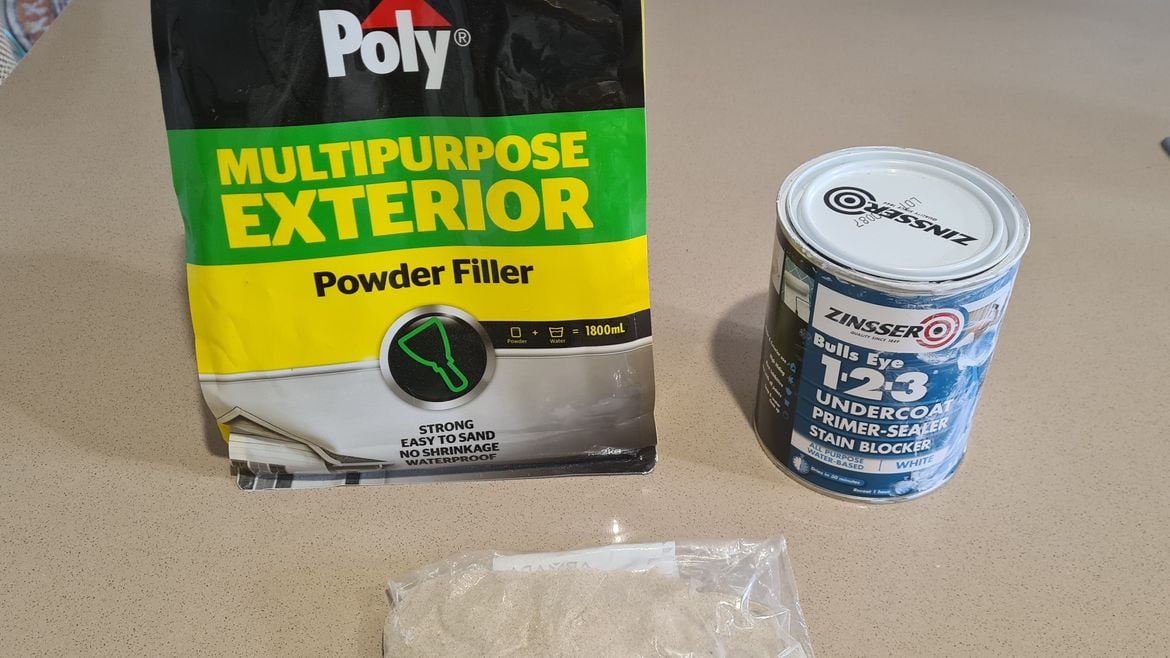

Poly Multipurpose Exterior Powder Filler.

Zinsser Bulls Eye 123 undercoat, primer-sealer an stain block.

Selleys Paint Over water based acrylic polymer.

Dulux Weathershield paint

70 x 35mm H3 pine framing I/N 8032103

Pine posts 100 x 75mm H4 I/N 0120811

Zenith pine screws 8-10 x 25mm

Taubmans Sun Proof paint low sheen I/N 1540464

Matrix1800 x 900 x 6mm charcoal fern screen panels. I/N 0092401

Hume 42 x 11mm moulding H3 treated pine I/N 0020927

Bamboo screen. I/N 3041187

Bastion post mix. I/N 0760294

Tools

Ryobi drill, Gorilla step ladders, small an large. Ozito Drop saw. Paint brushers. Hand saw an various small tools.

Steps

Step 1

Repairs to the render with Poly Multipurpose exterior filler an Zinsser 123 with course sand added. The repairs were taken back to a solid edge, filled an sanded smooth. A small amount of Zinsser was then mixed with course sand, an stippled onto the surface with a cheap brush, to create the render effect.

Step 2

The joints in the blueboard were cleaned out an filled with Selleys Paint Over acrylic polymer, smoothed level an coated with Zinsser 123. The Selleys product was chosen for the expansion capabilities, longlife an quality. Zinsser was chosen on reputation as an outstanding primer.

Step 3

After a gurney to clean the surface, the final step was two coats of a quality paint. Dulux Weathershield was selected because once again the expansion capabilities, colour retention an as a market leading product. The colour we selected was a bit way out, Pedirka Desert, so colour stability was an important consideration.

Step 4

The next step was the frame for the sunscreens with the single Matrix panel. The frame was 70 x 35 structural H3 pine screwed together with galvanised bugle batten screws 14g in various lengths.

Step 5

Following up by installing the Matrix 1800 x 900mm charcoal panels with 42 x 11mm slats at a 19mm spacing. The slats were H3 treated FJ pine an secured with screws suited to treated pine timber.

Step 6

The last step for this side was to paint with two coats of a quality paint. We chose Taubmans Sun Proof in Woodland Grey to match the garage door. The paint was good quality, suited to the application an cost effective.

Step 7

The other side with the two Matrix panels was much larger so it required a more substantial frame. 90 x 45 treated pine was selected supported on two 100 x 75mm H4 pine posts, concreted into the ground with Bastion post mix. The rest of the installation was a repeat of the first side.

Step 8

The last consideration was what to do with the space behind the sunscreens. An Oriental garden or a Mexican garden came to mind, why not both ? Old carpet was used as a weed mat covered by decorative stone. A bamboo screen, various plants, pots an statues were then added. Project complete. Over 80 percent of materials came from Bunnings.