The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Featured Projects

- >

- Home office drawers

Home office drawers

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Chest of drawers made with laminated timber panels.

The project

Following on from My simple D.I.Y. desk, I needed a chest of drawers to go with it for storing things. I started from the inside out - designing the drawers to fit 15.6" laptops and files, and then worked outwards to build the cabinet with drawer slides. I had 700mm overall height to work with, as that was the available height under the table where these drawers will slide under.

A huge shout-out to Harrison at Bunnings Pymble (Sydney) for doing expert level, extremely accurate and clean cuts on the wood panels. There was a lot of cutting and having it cut exactly to the dimensions I requested made my job so much easier.

Tools and materials

Tools and materials used in the project:

- Specrite 1200 x 300mm 18mm Timber Panel Hevea FJ Laminated

- SpecRite 1800 x 405mm 18mm Timber Panel Hevea FJ Laminated

- SpecRite 1200 x 600mm 18mm Timber Panel Hevea FJ Laminated

- Taskmaster Oslo 96mm Matte Black Handle

- Zenith 10G x 50mm Zinc Plated Hinge-Long Threads Countersunk Head Timber Screws - 15 Pack

- Goliath Standard Drawer Slide Pair - 350mm

- Carinya 25 x 25 x 40 x 1mm Galvanised Angle Bracket - 8 Pack

- Carinya 25 x 25 x 20 x 1mm Galvanised Angle Bracket - 20 Pack

- Move It 30mm 20kg Grey Swivel Plate Castor - 2 Pack

- Zenith 6G x 15mm Zinc Plated Hinge-Long Thread Countersunk Head Timber Screws - 45 Pack

- Taskmaster 10mm White Screw Caps - 100 Pack

- Cabot's 1L Satin Water Based Cabothane Clear Polyurethane Timber Varnish

- Monarch 50mm Woodcare Paint Brush

- Timbermate 250g Pine Wood Filler.

Steps

I planned for five drawers in the cabinet. Measuring for files and 15.6" laptops, the drawer dimensions were fixed as below:

| DESCRIPTION | LENGTH (MM) | x | WIDTH (MM) |

| DRAWER BASE | 400 | x | 280 |

| DRAWER SIDE | 100 | x | 382 |

| DRAWER BACK | 100 | x | 280 |

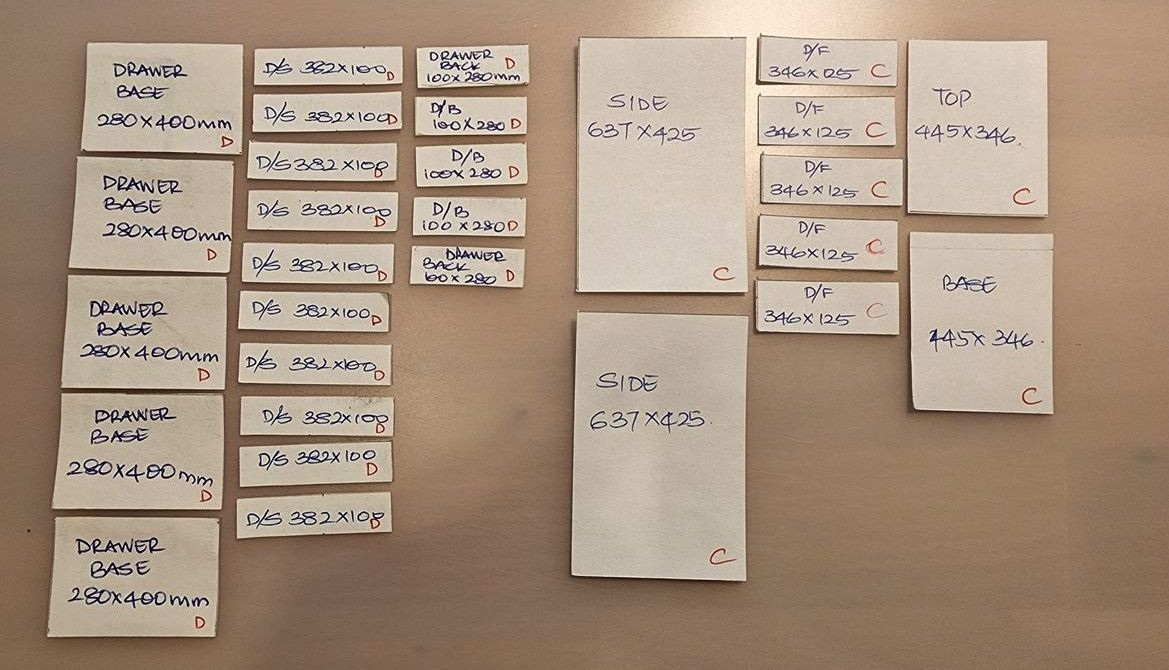

I cut out 10:1 scale models of the various sized pieces required in order to maximise the use of the available panel sizes and cutting requirements.

Once all the dimensions and cuts on the panels were identified, it was off to Bunnings to get everything and get the panels cut to size.

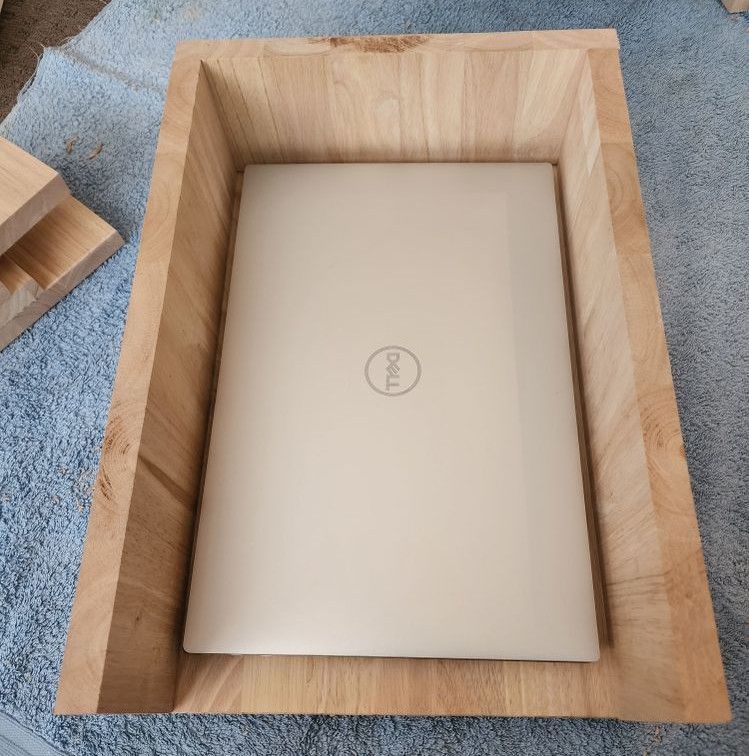

I started off first with making the drawers (without the front face), as per the above dimensions. I used long screws to screw the three sides onto the drawer base. Then I size checked with a 15.6" laptop for reference, with a little room to spare.

Mounting the drawer slides was a bit tricky. I mounted the drawer slides slightly below the centreline, vertically centred. This would allow the slides to run smoothly without fouling the drawers below.

Fitted the slides.

Once all the drawers were built and slides fixed, I used the off-cut pieces to measure and fix the dimensions of the cabinet.

Cabinet dimensions were fixed as below:

| DESCRIPTION | LENGTH (MM) | x | WIDTH (MM) |

| SIDES | 637 | x | 425 |

| TOP & BASE | 445 | x | 345 |

| DRAWER FACE | 125 | x | 345 |

| CABINET BACK | 309 | x | 637 |

I calculated a vertical space of 2mm between the drawer faces. Once the dimensions were fixed, off to Bunnings again to get the wood panels cut to size.

A lot of lines and markings to mount the drawer slides...

I discovered that rubber wood is a wood that splinters easily, so had to lower the drill speed. I had a couple of minor splinters like this, which were patched up with wood putty.

I counter sunk all screw holes with an 8mm drill bit, and then pilot holes of 3.5mm were drilled for 10G screws.

In addition to the screws, I used the Carinya Galvanised Angle Brackets (8 pack) on the inside of the cabinet for reinforcement.

Using the corner brackets on the insides of the drawers to mount the drawer face was a bad idea though - there was not enough space to get the drill driver to drive the screws in. It also impinged on the internal drawer space, so I switched to mounting the corner brackets on the outer side of the drawer. That was so much easier. All the excess drilling holes were later patched up with wood putty.

I used the Carinya Galvanised Angle Brackets as spacers to determine the mounting positions of the drawer faces.

Once drawer faces were mounted to the drawers, a quick check (and adjustment) of the slides to ensure each drawer moves smoothly and doesn't foul with the other drawers. Handles were then attached to the drawer faces.

All the maths, planning, adjustments and accurate-to-the-millimetre calculations later, all drawers moved smoothly and closed flush.

Now for the finishing touches. I removed the drawers, slides, and handles and filled gaps/excess drilling holes with Timbermate Pine Wood Filler and then sandpapered all surfaces with 80 grit sandpaper, then 120 grit and finally 240 grit sandpapers to get a smooth, almost silky finish.

I used Cabot's 1L Satin Water Based Cabothane Clear Polyurethane Timber Varnish - three coats were recommended, but I ended up putting on five coats because I wanted to finish off the can.

I used screw caps to cover the screw heads. Finally, mounted five Move It 30mm 20kg Grey Swivel Plate Castor wheels on the bottom of the cabinet.

All done. The Cabot's Satin Clear Coat gives a nice subtle sheen.

It weighs around 44kg unladen and has five castor wheels that can take 20kg each, so I'm confident this little thing can carry a fair bit.

More inspiration for your furniture project

Using premium timber from Bunnings, Workshop member Bundaboy built Pine chest of drawers for a friend.

Community member Tara built D.I.Y. bedroom drawers using recycled pallet timber combined with new timber pieces.

You can find more great ideas in our Top 10 most popular indoor furniture projects. Start a discussion if you need a hand and our community members will gladly answer any questions.

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects