The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Living and Bedroom

- >

- VJ panel wall ledge headboard

VJ panel wall ledge headboard

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

VJ panel wall ledge headboard

Simple to build and made with materials all sourced from my local Bunnings.

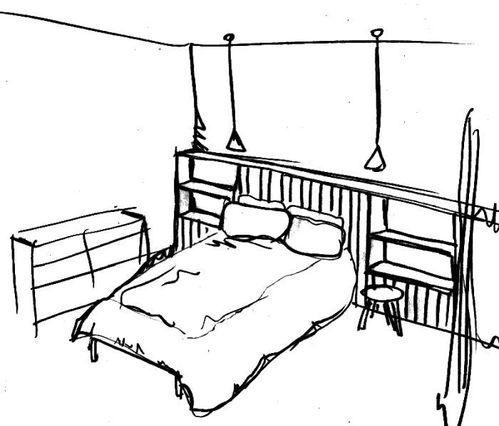

See below for the before photo of this project and keep reading to find out how you can achieve this result for a surprisingly low cost.

I'm going to walk you through step by step from the start to finish of this DIY project.

First, I wanted a deeper ledge so I needed to decide which size top to use.

You will want to decide this depth before building your frame so that you know what size to make it.

I went with a 184 x 19mm 2.4m DAR Pine Premium for the ledge top.

Before I fully committed to this depth and timber type I tested it by holding it up against my paint colour in the room.

Next step was to build the frame.

I wanted a 5mm lip on the underneath of the ledge between the top of the ledge and the panel.

So I subtracted the the 9mm for the panel + the 5mm lip from the 184mm of the ledge.

That tells me that I need to build the frame at 170mm depth from the wall in order to achieve that look.

I used 70 x 35mm Framing MGP10 H2 Blue Pine for the frame.

Overview: I built 2 x flat facing wall frames and then joined them together at the 170mm depth.

I started by building the first frame on the floor to make it easier to nail in the studs.

I nailed my frame together using my favourite tool the Paslode FrameMaster Nail Gun

Now thats a fun tool! I nailed it with Paslode 75 x 3.06mm Bright D Head Framing Nail

I spaced out the studs according to the VJ panel specifications.

You can find the installation guide / videos / specs here Easy Craft VJ Guide

The studs need to have a 600mm centre because the panels are 1200mm wide.

So you want to make sure your panel is supported with a stud behind it, on the end, the middle and the join.

The best way to check is to cut a piece of timber at 1200mm wide and lay it across your studs between your pencil marks.

Now in regards to height. I made my wall extra high at 1200mm and built the frame to suit.

If you want to achieve this, you will need to get the Easycraft 2400 x 1200mm 9mm Lining Panel sheets and then cut them in half at 1200mm.

This is what the two frames looked like against the wall before adding the block spacers and noggins.

You can see how I tested my timber piece by placing it on the ledge top to check I was on the right track with the frame.

I also had a scrap piece of VJ panel which I checked on the front to ensure I would achieve the 5mm lip.

Next I cut my blocks at the depth that I wanted my frame to be which was 170mm.

I then nailed the blocks in on the top and bottom to join the two frames and maintain the correct depth as below.

I then added in the noggins as per the recommended 450mm height/distance.

With noggins its best to offset them so that you can still nail from the other side.

The noggin is a horizontal timber between the studs to support the space behind the panel.

Extra tip: Before bolting my frame to the wall I removed my flooring around it, so that the frame would sit on the concrete. You can skip removing the flooring if you want the project to be easier.

I bolted my frame to the wall using the easy Ramset AnkaScrews

You can also see how I nailed a stud in that would sit flat against the wall, one on either side and one in the middle. This was to allow for a point where I can put my fixings from the frame, through to the wall.

Next step was to add the Easycraft 2400 x 1200mm 9mm Lining Panel

As mentioned, I cut mine in half at 1200mm in order to achieve a higher ledge.

If you want to skip that step to, you can go with the Easycraft 900 x 1200mm height panels which are 900mm high already.

Or if you want to step it up you can use the new 2400 x 1200mm 12mm Primed Scallop Profile which would look amazing.

When installing the panels I went from left to right and started with a full panel. Some instructions will tell you to find a centre first so that both your ends are even.

I personally don't think it's worth the effort, as the end thats cut is not something you notice in the long run.

I applied Acryclic Stud Adhesive on the studs as per the specifications to help the panels stick on.

I then nailed the panels on with a brad nail gun. I didn't put too many nails in because I knew I had to patch the holes before painting.

Extra tip: When attaching the panels, I made sure the top was completely flush to ensure I would get a nice clean edge under where the ledge and panel meet. I also used the factory cut edge at the top to make sure I had the cleanest line.

After the panels are attached you can then fill in the nail holes. I used Selleys Spakfilla because its easy to work with, fast drying and nice to sand.

You then need to fill your joins between the panels and where it meets the walls with gap filler, Selleys No More Gaps is my go to. I like to check my products and support Australian companies whenever possible.

Now its time to paint!

I painted my panel and the wall behind it before putting my timber top on to get those nice crisp lines.

You can see below that the top hasn't been installed yet, keep scrolling to see the result of installing it after painting.

The result:

Now with the top, I had a long distance to cover at 3900mm wide.

Dressed timber in the 184mm does not reach that distance. So I purchased one of the longest lengths and then a shorter one to make the difference. I cut a 35 degree angle on the flat face of both pieces to make the join and it worked out well.

I simply adhered the top on using Selleys Liquid Nails and put some weights on top while it dried.

For an extra precaution I also put some Gorilla Wood Glue on the join to ensure it didn't seperate over time.

I didn't want to nail or screw the top because I wanted that extra clean look. Its holding up well and isn't going anywhere anytime soon.

Feel free to reach out, If you have any questions or want help with this project.

You can also find me at https://www.instagram.com/therenodad/

And @therenodad on all other socials.

Luke | @TheRenoDad

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: VJ Panel Wall Ledge Headboard

What an amazing transformation, Luke (@TheRenoDad)! I absolutely love what you've achieved here. I trust you're thrilled with the results.

I rent, and you've got me thinking I could pull this off without permanently fixing it to the wall. It seems relatively stable, and I'd have a king-sized bed pressed hard up against it. I don't think it would go anywhere, and I could attach it to the bedhead if needed.

Many thanks for sharing and including such thorough details for our members to follow. I trust you'll have plenty of questions as wall panelling is always a hot topic here.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: VJ Panel Wall Ledge Headboard

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: VJ Panel Wall Ledge Headboard

Hi again @TheRenoDad

Looking closer - being a book man myself - it wouldn't be too hard to include shelving with this project?

You did an excellent job removing those floating floor boards - was that difficult or are they a different style to the usual click method?

Did you remove that round ceiling light?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: VJ Panel Wall Ledge Headboard

Hi Graeme,

Thank you for you feedback.

Yes, I think this is a great idea and the shelves could be incorporated into the frame with a bit of extra work.

You could also quite easily match the internal shelves of the headboard by using the same timber as the ledge top for the shelving tops.

There is definitely something to be said about the experience of reading a good book.

Thanks again,

Luke

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: VJ Panel Wall Ledge Headboard

Hi Graeme,

This is very observant of you!

Thanks for taking the time to thoroughly read the article.

This is actually where an old analog phone point use to be.

It only had the phone data cable running into it, hence the small hole though the wall.

Thanks again,

Luke

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: VJ Panel Wall Ledge Headboard

Thank you Mitchell!

I was happy with the result, my wife even more so, as I surprised her with this reno on her return from a trip to Ireland.

That is a brilliant idea to adapt this to a free standing bed head and would be more than stable enough. Especially, as you said with a bed base supporting it.

Also a consideration for anyone out there that's handy is to create a side hustle out of building these bed heads and then selling them.

Thank you for the welcome into this community. I look forward to connecting with like minded DIY'ers.

Luke

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: VJ Panel Wall Ledge Headboard

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: VJ Panel Wall Ledge Headboard

Hi Graeme,

Also just noticed your other question.

Yes, I removed the old round ceiling light.

I cut a square hole where it was to put a square piece of plaster into it to make it easier to patch.

Then I gave it a coat of plaster over the whole thing, followed by a top coat of plaster.

Cheers,

Luke

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.