Step 1

I cleaned the work area wider then I expected to use, just in case. As I was the offsider/labourer, I wanted to have as much done as possible to save my carpenter mate extra time. Plus to save money, of course. This is the start of the garage retrofit to lockup/secure stage.

Framing with a nail gun made life a lot easier. We used the nail gun to tack the timber together and then put in two timber screws to each join.

Yeah, mistakes happen but can be worked around. The door frame plus the pre-bought upper window just would not fit. Close, but no go, so the solution was to use the face timber to hold the space and frame the rest.

The sliding window in place. I was happy with the solution.

Step 2

The side door I wanted fitted into the same area as the old side window. The lintel didn't have to be changed; only two cuts down through the brickwork and across the base were needed. The gas pipe that ran along the side of the house had to be moved also. I wanted to have access to the little courtyard area, as it was dead space.

I wasn't around when the carpenter cut the brickwork. I think he figured to send me to Bunnings for something to get me out of the way.

You can see the gas pipe going around the door area.

Prepping the underside of the doors with oil so I wouldn't have to worry when they were in.

Framing up the side door. It went so much easier than I expected.

The Pine facing really brought it together.

Step 3

The doors I bought from outside Bunnings. I only had a short timeline to get them so we could install them. Solid exterior doors. I used three sets of hinges per door as they were heavy. The glass panes were supplied by my carpenter friend (either off-cuts or cut to size). I was surprised how easy it was if you knew what was the next step.

Things to consider is what will be behind the open door. I hadn't thought of it or potential dead space area.

Making sure the door could be closed with the existing roller door still in place. The glass pane (one piece) had not arrived yet.

The beading around the glass frame went in so easily.

Backfilling the nail holes with putty before sanding and oiling.

Preparation for oiling the timberwork.

Step 4

The last steps were oiling and making sure I took the tape off in a timely manner. I must admit I have been slack sometimes, and then the tape sticks to the paint or vice versa.

My carpenter mate really pushed me to seal the timber within days. The sun will discolour it fast.

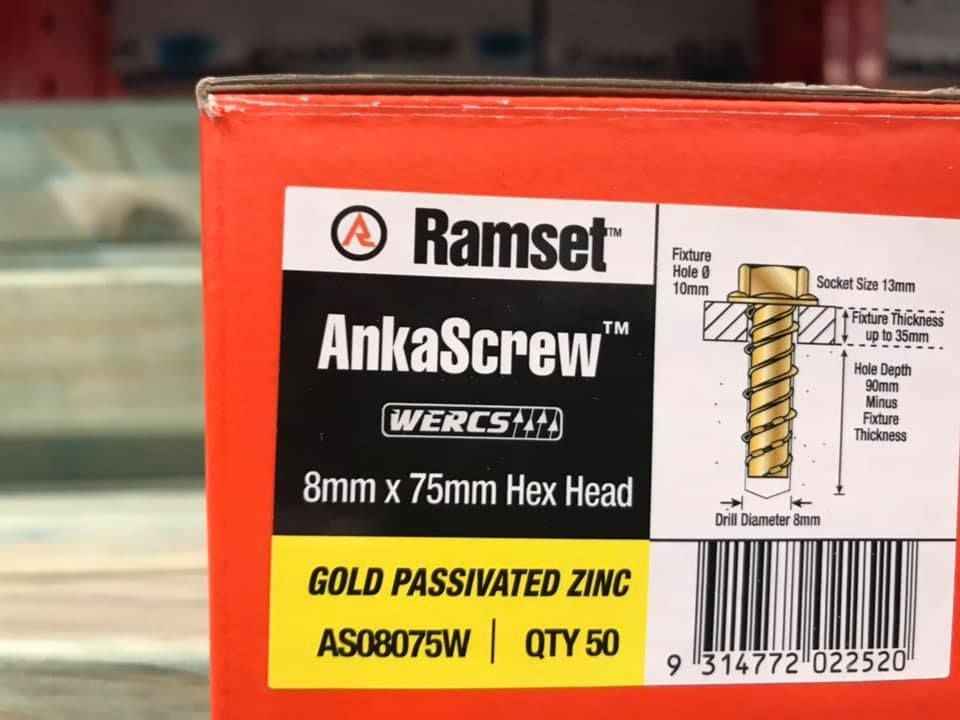

I used these to fasten the frame to the concrete. I had never come across them before as I had only used Ramset bolts. These worked a dream, very easy to use and even back out of. Make sure the hole is empty of all dust. I snapped my socket wrench by trying to screw one in with dust in the hole.

I used three hinges on the door, figuring that timber can warp so I went with a middle hinge on each door.

The middle horizontal is the part that covered the weep holes. Both doors work well and there is a sloped piece to allow the water to run outside at the bottom of each door.

The garage is remarkably cool in summer and warm in winter. I generally leave the door open and get a nice breeze coming in. With that large window, I thought I'd better do something so I have actually used interlinked CDs, hanging off timber strips.