The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Garage and Shed

- >

- Re: Folding and rolling mitre saw statio...

Folding and rolling mitre saw station

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Folding and rolling mitre saw station

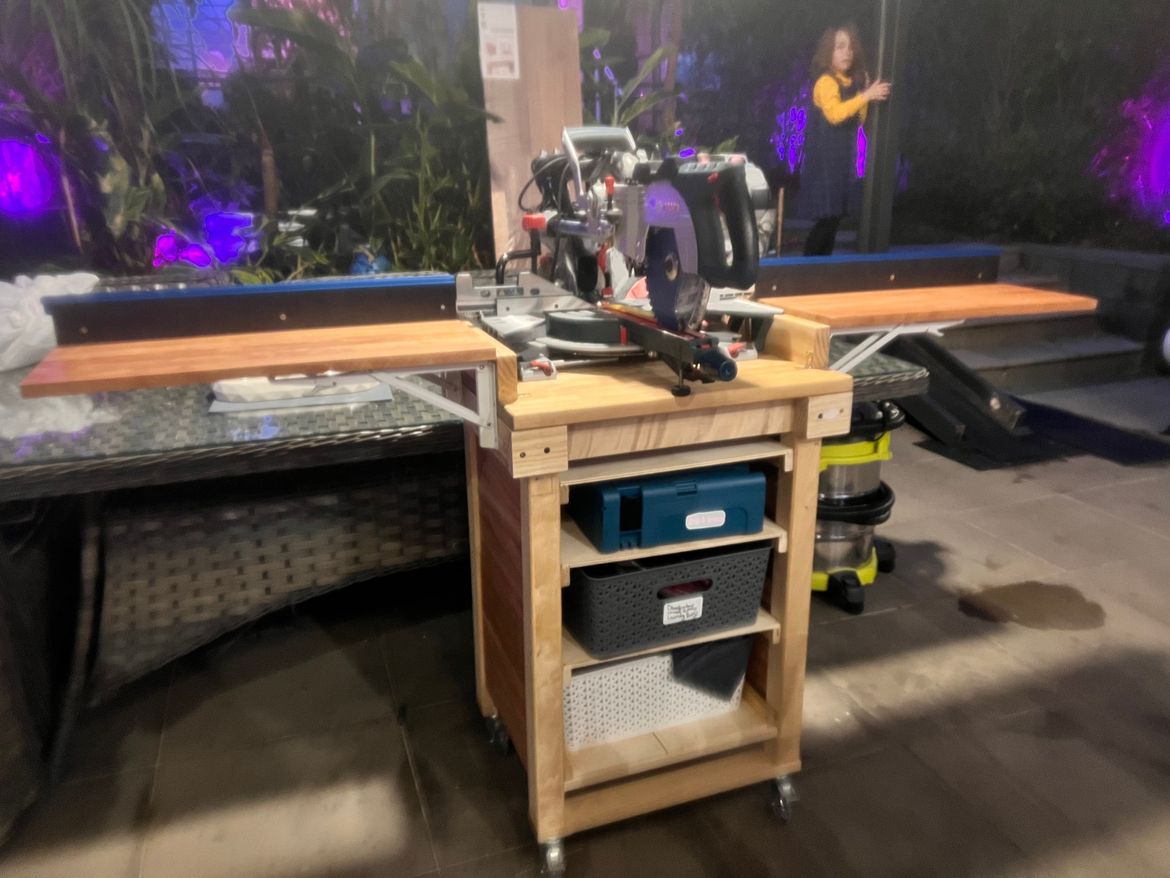

I have a tiny shed - 2metres by 900mm. It’s basically to store my tools and I bring them out into the backyard to make things. I wanted a way to create Rolling tool chests that also housed my big tools like my mitre saw and Table saw. I wanted them to be kinda like transformers- become a fully operational workshop when I need, but quickly fold down and easy to put away, because I am a mum and have limited time to build things, and I don’t like having tools out when little fingers are around.

So this is the mitre saw station. I Hacked an ikea butchers block I had and built folding wings with a fence that will allow me to add stop blocks. Overall cutting surface is 1.8 metres which is awesome. Currently I have shelves but will put 4 drawers in to hold tools.

I love the fact that I can roll out, plug in and fold out my station in less than 5 minutes.

Materials

- Old ikea rolling butcher block

- 4 75mm castors

- 70x30mm pine around the edges to make the sides flush with the top and next to the saw to allow me to add fold up hinges

- 4 folding locking hinges

- 2 Okumu 305x1200 panels to fill in the back and sides of butchers block

- 2 42x19 pine battens split in two to make runners for shelves but eventually drawers

- 1 Okumu 305x1200 panels split in half to create the wings

- 2 42x19 pine battens Laminated together to make the back fence support

- 2 600 mm x 60 mm strips of form ply to make the front of the fence

- Kreg Trak and stop kit to sit on top of the fence and allow me to slide on stops and it also has a measuring tape on each side

Tools

- Mitre saw

- table saw or circular saw

- Drill

- Driver

- Kreg Pocket Hole Jig

- Measuring tape and square

- safety gear

Steps

Step 1

1. Strip out shelves in old butchers block

Step 2

2. Cut Okumu panels to size to fit back and sides of butchers block

Step 3

3. Cut 1 okumu panel in half for the wings

Step 4

4. Cut 70x30 pine to size to wrap around the back and sides of cart frame

Step 5

5. Cut two pieces of 70x30 pine to the same width as the okumu wings

Step 6

6. Laminate 2 pieces of 42x19x1.2 pine together and clamp

Step 7

7. Cut two pieces of form ply or whatever you have on hand to 600x 60 mm for the fence

Step 8

8. Trim two of the cart legs to the same length as the other two that already have wheels on them.

Step 9

9. Sand and seal all timber including butchers block top. I used Osmo.

Step 10

10. Drill pocket holes in Okumu panels for the side and back.

11. Attach okumu panels to side and back between the legs, making sure they are flush with top rail.

12.Attach 70x30 pieces to the side and back so side is now flush with top.

13. Split some 42x19 by 1.2m (3 approx) in half so now 21x19 and then cut them to length to act as runners for your shelves or drawers.

14. Attach runners at your desired intervals to create shelves.

15. Cut some 7mm ply to size to act as shelves and attach to runners.

16. Attach butcher block top back to the top.

17. Add 4 castors to the legs

18. Centre mitre saw on the butchers block

19. figure out where to place your wings so your wing fence lines up perfectly with your mitre saw fence and your wings are level with the plate of mitre saw.

20. attach the last two pieces of 70x30 pine to the top of the butchers block in the position you have marked above

21. attach the 4 folding hinges

22. cut your laminated 42x19 pine in half

23. attach pine to back of wing

23. attach form ply fence to wing and pine backer - make sure to countersink screws

24. take two pieces of the Kreg track stop and drill holes and screw into fence.

25. Clamp wings to fold up hinges and ensure that everything is flush and square

26. attach wings to hinges.

27. Add measuring tape to Kreg track stop on either side and attach stops.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Folding and Rolling Mitre Saw Station

Thank you Noyade.

Yes it is a Bosch. It’s a lovely tool. I have been slowly upgrading over the years from my Ozito collection as they die. It was a birthday present from my family.

wheels make such a difference don’t they! I look at all these guys on YouTube with “small workshops” and laugh. They have no idea what small is lol.

thank you again!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Folding and Rolling Mitre Saw Station

Sorry and yes the saw is bolted down. I only put two pieces of 70x30 pine on top of the butchers block to help with attaching the hinges but the rest of the butchers block is clear so the saw can move freely.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Folding and rolling mitre saw station

Thank you Dave.

yes I know that problem well lol. I had to do the same with mine and I found it would put me off doing projects because of the effort it would take to set up and break down. I am just finishing off the rolling table saw now and cross cut sled and then onto some bookcases and a long run of built in cabinets. So plenty to keep me busy at the moment!

the Kreg stop is great! However I will say that’s it’s annoying that it only comes with imperial measuring tapes. I found another set by a company called UJK which is actually better quality and made in England so is metric. They also make lots of other interesting jig and benchtop bits and bobs. You can find them on a website for Axminster tools and they ship to Australia. I would recommend their set over the Kreg for those reasons.

many thanks again and send us a pic of your cart when your done!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Folding and rolling mitre saw station

Hi Noyade

Thank you! Yes an accurate fence is so important and having a long one with stops is awesome for repeatability, certainly makes things quicker!

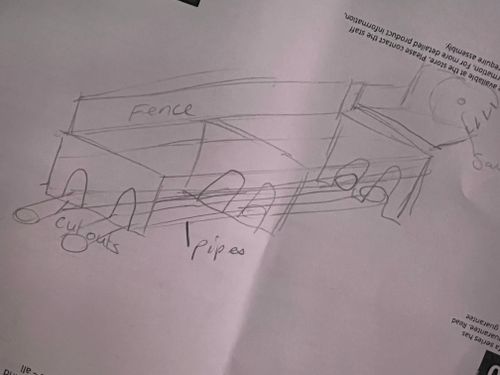

thinking about your set up I would build two wings to sit on top of bars. I am thinking two long box’s upside down - the top would be inline with flat plate of your saw and you could attach a long fence to that top. You can build one for each side. The bottom of the upside down box would have some cut outs so the bars can slide up into the box and allow the box to slot on top and not fall off. I did a quick sketch - apologies as I am no artist.

you could even put a bottom on the box above the bars and make part of the top open up and you can store track stops and clamps etc in there.

hope you kinda get what I am trying to explain.

let me know what you think.

cheers Sian

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Folding and rolling mitre saw station

Thank you Tedbear! I can’t wait to take it for a spin this weekend!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Folding and rolling mitre saw station

Good morning Sian @RainbowDiY

Thanks very much for your doodle. 😁

But I'm thinking there may be too much flexing in the extension bars and play within the cut arches for fence accuracy - they would have to be absolutely perfect. So I'm giving up (for the moment) on fence extensions on the Ozito support frame.

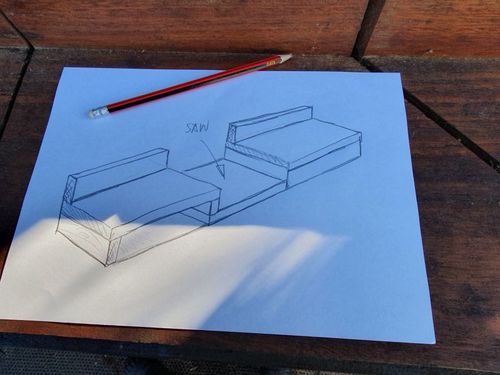

Instead, a doodle in return - a simplified 'poor man's' version of what you have superbly created. Sorta like an Olympic podium, but for two winners and one loser.

Possibly using those wooden kitchen tops you see at Bunnings. I'm thinking the wood fences would need to incorporate some form of fine adjustment?

Is that what the Kreg Trak product does?

Or maybe a steel fence back section would be better - more accurate? 🤔

Partially inspired form a wooden fence I reconstructed 20 years ago - plus yourself. 😁

It forms the fence for a very old Australian saw (but on wheels now!).

But it's too cumbersome compared to today's compound mitre saws.

Cheers.

Graeme.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Folding and rolling mitre saw station

Hi Dave

That looks like a great idea. Yes the Kreg track stop does allow you to dial in some fine adjustment. However I got the Kreg stop kit on special when they had a sale. I have since then being doing a lot of research to do a table saw sled. I came across a British website called axminster tools and a company called UJK. I purchased their kit for my table saw sled.

They both ultimately do the same thing. However the UJK one comes with a metric stick down tape where as Kreg only does imperial. I actually used the leftover tape from my cross cut sled as the tape on my mitre saw.

I will also say they are nicer quality. No plastic bits etc.

I have also seen people rout in T track into the vertical piece of the fence and run a block of wood with a t track nut and handle along it - that looks like a very effective and cheaper method. I have also seen it done on big built in mitre saw stations with t track running all the length of the bench on the bench top itself with a block of wood and t nut. Also looks effective.

Below are the links to the different kits:

https://www.kregtool.com/shop/cutting/miter-saw-cutting/precision-trak-stop-kit/KMS8000.html

https://www.axminstertools.com/global/ujk-technology-track-stop-kit-101500

If you search You Tube there are many videos and some fab ideas that may help you as well.

Best of luck !

cheers

sian

- « Previous

-

- 1

- 2

- Next »

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.