The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Living and Bedroom

- >

- How to restore table: Epoxy, lacquer or ...

How to restore table: Epoxy, lacquer or polyurethane?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to restore table: Epoxy, lacquer or polyurethane?

Hi,

My dad made this table from scatch on my pops woodturner when I was about 5yrs old. I been given it as a family heirloom and it really needs some T.L.C. So Ive almost finished sanding it back to raw wood and its looking fantastic. Im not sure if I should stain it. The end result I would love is to have that thick super glossy finish. Now for the decision Im finding quite hard to decide on. Do I lacquer, epoxy or polyurethane? And what grad of sandpaper should be the last I use before applying any of these solutions so it sticks properly. Ive only used an 80 grit sandpaper. Obviously I do not want to ruin this piece of my families history. I would love some expert advice. So please help me.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to restore table: Epoxy, lacquer or polyurethane?

Hello @olemate

Welcome to the Bunnings Workshop community. It's wonderful to have you join us, and thank you for sharing your question about how to restore your table.

You've done an excellent job in preparing the table. Sandpaper works in degrees of roughness. The lower the number the rougher the sanding surface. As you climb up in numbers you'll notice that the sandpaper gets smoother. So using 80 grit sandpaper will strip the old paint and give the timber a rough surface. This produces surface splinters which need to be removed before applying polyurethane so that you get a flat smooth surface.

To remove those splinters, I suggest using 240 grit and finishing off with 400 grit to have a flawless surface. It will feel smooth to the touch and will not have any splinters standing up.

The hard part is choosing a finish. To have a very good idea of the finish, I suggest visiting your local store and looking at the polyurethane sample finishes on display in the paint department. Once you've chosen your varnish, I recommend getting a Pro Renovator Measuring Cup Set - 3 Pack. Look carefully at diluting rate at the back of the can so you can test it on the cabinet.

To get that high gloss finish that you're after you'll have to do several coats. Test a small section of the cabinet with the diluted mix and observe the finish once it's cured. Rub it with the 400 grit sandpaper and wipe the dust off with a damp fibre cloth. Place a second coat with a lower dilution rate. Wait for that to cure. Repeat the process of rubbing with the 400 grit and wiping with the damp fibre cloth. The final coat should be the lowest dilution rate.

I understand that the testing is a long-drawn-out process. But this is the best way to find out how the timber will behave once you've started coating it. If you decide that you wish to use a lighter finish or one with a stain, you can easily sand off the test area and begin again. Once you decide on a final finish you can then commit to painting the whole table.

My number one tip for your project is to get the best possible paintbrush or roller that you can get. Using a substandard paintbrush will ruin all your hard work.

Here is a handy step-by-step guide: How to restore wooden furniture

Here are some tables with amazing finishes our Workshop members have shared.

Let me tag our experienced members @LePallet, @dean, @Nham and @jeevanfranciz for their recommendations.

If you have any other questions we can help with, please let us know.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to restore table: Epoxy, lacquer or polyurethane?

Hi EricL,

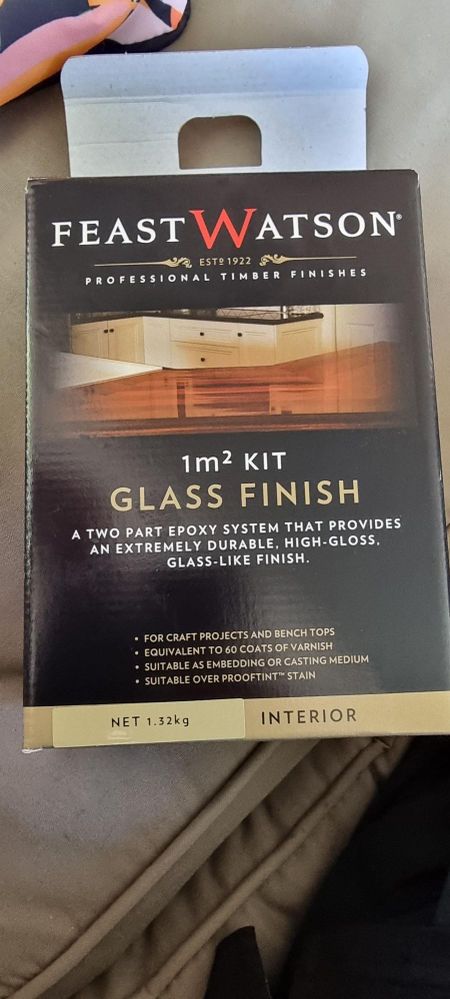

Thats exactly the type of advice I was looking for and very much appreciated. I would like to throw this idea at you also and see your thoughts on it. I have Feast Watson Glass Finish which is an epoxy system (see attached pic) and I would like to fill in the turned grooves (see attached pic of the grooves to be filled in) which are featured on each of the 4 sides of the table and I only want to use it to fill in the grooves and leave the rest of the table to be coated in polyurethane as you have suggested. I have my own ideas on how this could be done but I would like to hear your thoughts.

As you can tell I still have some sanding to go.

Thanks Brett

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to restore table: Epoxy, lacquer or polyurethane?

Hi @olemate

This activity you're about to embark on falls under tricky and difficult. If done correctly it will look amazing, done badly it will look very bad. The tricky bit is making a temporary frame to catch the resin in place without dripping out. The resin will settle flat and will form corners that will have to be sanded down. You then have to remove the frame without damaging the resin that's attached to the wood.

The difficult part is sanding it down so that it will be at the same level as the timber edge. You'll then need to use high grit numbered sandpaper to bring back the polish of the resin. If done correctly, the resin will fill in the gaps of the turned wood and produce a glass-like finish.

Let me tag our experienced members @TedBear, @Brad and @LePallet for their recommendations.

If you need further assistance, please let us know.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to restore table: Epoxy, lacquer or polyurethane?

Corflute might be flexable enough to tightly wrap around with the edges siliconed to stop leakage, not sure on the gap between the pieces if it can be done as a double pour with the corflute filling the gap or one piece trying to follow the curves and making sure to block the inside of the two pieces. Corflute should peel away from cured epoxy.

Some random thoughts...

If expoxy finds a gap it will go there, unless you really want it to fill the gap.

Painters tape can and will fail at will.

Epoxy is self leveling.

Wet and dry paper is needed if your going to get a nice hand sanded finish.

Blue compound for a powered buff.

Don't mix compounds on a buff!

5 minute epoxy can fix some imperfections.

Superglue sets hard for small areas.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to restore table: Epoxy, lacquer or polyurethane?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to restore table: Epoxy, lacquer or polyurethane?

Hi @olemate,

In my experience, you'll never find a filler that will match your timber exactly, and any clear coat will only accentuate the difference. Timber, even from the same species, varies dramatically from tree to tree, so the Pine filler wouldn't be exact even if you were trying to match Pine. To try and fashion an invisible repair is not something that can be achieved with a putty. A furniture restorer would source the exact timber in the same colouring and cut out the damaged portion before grafting/plugging in the new timber to match.

There are techniques where you collect the sanding dust from your timber and mix it with PVA glue to create your own filler. This will generally get you to a closer match than anything off the shelf. However, you'll still be able to see the repair.

How significant are these repairs, and how many are there? I think you might be being a little hard on yourself and overly concerned with these imperfections because it is a family heirloom. I do this myself, and I get highly focused on things others wouldn't even notice. However, I can also relate that you'd like the table to be without imperfections. Prior to you starting this restoration, we can see that the original filler used on the table also didn't match. Whether invisible or not, your repairs are a sign that someone cares for this table. You've done an outstanding job and should be proud of what you've already accomplished.

The only way I can see you concealing the colour difference is staining quite dark. The darker you go, the less noticeable the colour difference will be. However, you might like to dig the current filler out and try something in a different colour. Perhaps you could get a few different colours to test.

To see if they have any thoughts, let me mention some of our knowledgeable woodworking enthusiasts, @Brad, @r23on, @JoeAzza, and @Nham.

Please let me know if you have any questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to restore table: Epoxy, lacquer or polyurethane?

Thanks MitchellMc. I don't know why I didn't think of keeping the sanding dust. That would have been the best option. Too late now. I will have to consider my options. So far stain, dig it out and leave the imperfections so the natural wood shows through or leave it as is and start the epoxy. I will wait and see if anybody else has any other ideas first though. However I think your on the money with all the advice. Thankyou! I appreciate all your feedback.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to restore table: Epoxy, lacquer or polyurethane?

Hi @olemate, since it is only the top surface of the fills that can be seen, you may not need that much sawdust to make up a surface coat, if you only dig existing filler out a little. Is there a place underneath with the same timber, where you could sand some off and collect the dust? A belt sander with a clean bag attached would do it best, but other methods can work too.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to restore table: Epoxy, lacquer or polyurethane?

Its a possibility. I dont have a sander that has a bag attached. I suppose I can place a clean plastic sheet underneath that can collect the dust. Nice option TedBear.

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.