The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Bathroom and Laundry

- >

- floor flashing for bathroom and shower

floor flashing for bathroom and shower

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

floor flashing for bathroom and shower

hi,

I have used the brutus 50 x 70mm flashing for the floor in the bathroom and the corners of the shower. I used fc11 to seal it to the cement sheet and the corners where it meets. I noticed after it dried 15 hours later I can easily peel it off the pvc. I have read you need to scruff up the surfaces for it to bond properly. It has stuck to the cement sheet on the bottom side but not the joins.

Do I need to take any other steps or is there a product thats better to use? Thanks alot

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: floor flashing for bathroom and shower

Welcome to the Bunnings Workshop community @conorjames. It's tremendous to have you join us, and many thanks for your question about bathroom flashing.

Did you scuff up the PVC flashing surfaces before applying the Sikaflex 11FC? Sikaflex products generally rely on good surface preparation to achieve a strong bond, especially on smooth plastics like PVC. If the flashing was left smooth, that is very likely why it has adhered well to the cement sheet but is peeling away at the joins. Lightly abrading the PVC with sandpaper to dull the surface, then cleaning off any dust before reapplying the sealant, usually makes a big difference. If that step was missed, it would explain exactly what you are seeing and is a good place to start fixing the issue.

Please let me know if you have any questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: floor flashing for bathroom and shower

Thanks Mitch, do I need to use a primer

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: floor flashing for bathroom and shower

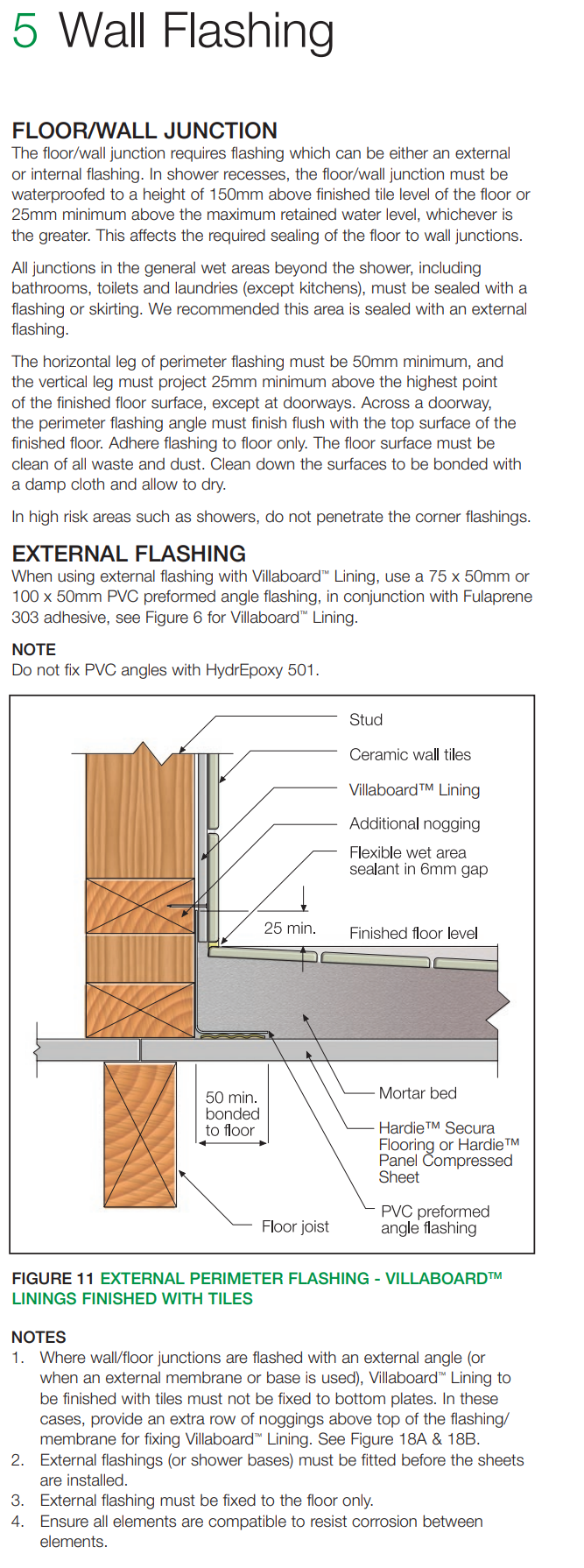

Scuffing it up should be suitable @conorjames. I'm just going through the James Hardie Wet Area Installation Guide, trying to find a reference to the approach you're taking. Typically, you would just bring your wall sheets down and finish just above the floor, then seal that gap with Sikaflexx 11FC. The membrane is then painted over the corner using waterproofing tape. This flashing is not a waterproofing element; it just gives you a neat corner to work with.

I'm just wondering whether this moulding is needed at all, and it might be best to confirm with your waterproofer whether it's necessary.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: floor flashing for bathroom and shower

Hey mate,

I scuffed all the pvc brutus flashing with sandpaper, put more fc11 on it left until today its only slightly better. I used gyprock wet area silicone on one area and that works way better. I have wasted 200$ on fc11 🥲

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: floor flashing for bathroom and shower

Thanks for the update @conorjames. Please note that Sikaflex 11FC does not suggest it is capable of adhering to PVC in its technical data, and it also achieves maximum strength after 28 days.

The flashing you are installing only needs to be bonded to the floor and held in position. So, if the flashing is held in position, that's all that is needed. The James Hardie installation guide recommends a neoprene-based adhesive for this bonding. They would potentially adhere the moulding better as they are designed to glue plastics and PVC.

Are you planning on applying a membrane over this area? Without knowing more details about your installation, it's difficult to know exactly what the requirements are.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: floor flashing for bathroom and shower

Yeah the water proofing is happening next week

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: floor flashing for bathroom and shower

Will you be pouring a mortar bed @conorjames? If so, provided the moulding is held in position, it should be fine to go ahead with that. It might be worth speaking with your waterproofer to confirm the current level of adhesion of the moulding.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: floor flashing for bathroom and shower

He is going to be using self leveler in bathroom and mortar bed in shower, this should stick it in place, ive used the gyprock stuff its working much better, is there a silicone like product that sticks to pvc better I can use for the expansion joins , thanks

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.