Bunnings Workshop is under maintenance and read-only.

The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- How To

- >

- How to make a cheese board

How to make a cheese board

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Difficulty: Beginner

Impress friends and family at your next gathering with a D.I.Y. cheese board. This guide shows you how to make a two-tone timber board perfect for an antipasto platter.

Steps

Step 1

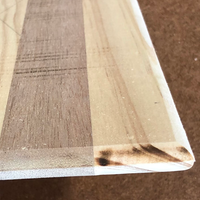

When selecting pieces of timber, ensure that they are straight, and the edges are free from any damage. Cut three pieces of Pine 395mm long. Cut two pieces of Meranti (or your timber of choice) 395mm long.

Order the timber in a combination you feel looks best. At the end of each piece mark the growth rings, and rearrange so that each piece's growth rings alternate. This will ensure that your board does not bow over time. When the order is finalised, number each on the top face to ensure you maintain the correct order throughout the project.

Step 2

Align the pieces to ensure the ends are level. Using a try square, rule a line through the middle of the pieces, avoiding ruling to the outside edges.

Set your biscuit joiner to a 9mm depth to cut at the centre of each edge. Set the biscuit cutter to size 20. Joining your timber using biscuits will significantly improve the strength of your joints and make gluing easier by keeping everything in place.

Clamp each piece to your workbench to cut the biscuit holes one at a time. Keep the number face up and make sure that the front plate of the machine is held flat on the face. Align your ruled marking with the indicator and push the machine in to its full depth. Cut only the inside edge of the first and last piece, and both edges on all other pieces.

An alternative to the biscuit joiner would be using dowels and a jig to complete this step.

Step 3

Arrange in the correct order and do a dry fit of all pieces with biscuits in to ensure all biscuit holes have been cut to the correct depth.

Place the first four pieces with the edge up and spread a good amount of PVA glue along the edge ensuring some goes into the biscuit holes.

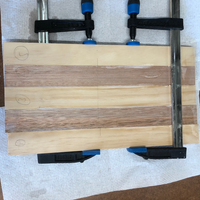

Place biscuits in their holes and clamp together using F clamps on alternate sides of the board to avoid bowing the timber. Align the markings and tighten until you see the glue beading between each joint. Avoid over tightening as this may cause the board to bow.

Wipe away excess glue on both sides with a damp paper towel. Clamp a piece of timber across the face to hold it in place and allow the glue to dry overnight.

Step 4

Using a try square, mark a straight line along the end of the board, ready to trim the ends.

Clamp a scrap piece of timber down as a guide, allowing you to cut straight through your marked line. Cut both ends so they are even and square.

Step 5

Mark a 38mm hole on one end of your board.

Clamp the board with a piece of scrap timber underneath. This will avoid the timber breaking on the underside.

Cut a circle using a hole saw, being careful to hold the drill upright.

Step 6

Set your router bit to cut halfway through the board’s thickness.

Secure the board by clamping to your workbench. Place the router base plate flat on the face of the board, with the router bit not yet touching the edge. Start the router away from the edge and slowly move in to cut the edge and push slowly along the edge, from left to right. The bearing will control the depth of your cut.

Repeat on each edge, on both sides around the board, and inside the handle.

Step 7

Sand the edges of the board starting with 120 grit and then finishing with 180 and 240 grit. Pay attention to any burn marks made by the router.

Sand the face of the board with a detail sander, again starting with 120 grit and finishing with 180 and 240 grit sandpaper.

Step 8

Using two lint-free cloths, finish the board with food-safe wax. Use one cloth to rub wax into the board with the grain and around the edges. Buff excess wax away with the second cloth. Repeat 2–3 times.

Enjoy a picnic with your new cheese board.

Materials

-

1 piece of Porta 40 x 18mm x 1.2m Pine DAR

-

1 piece of Meranti 40 x 18mm x 1.2m DAR

-

Bottle of exterior PVA wood glue

-

Packet of size 20 biscuits

-

Tin of food grade wax

-

Paper towel

Tools

-

Mitre saw

-

4 Irwin 150mm quick grip clamps

-

2 F clamps (300mm minimum)

-

Pencil

-

Try square

-

Biscuit joiner

-

Jig saw

-

Drill

-

38mm hole saw

-

Router

-

Round over router bit 10mm radius

-

120, 180 and 240 grit sandpaper

-

Detail sander

-

Safety glasses

-

Hearing protection

Images

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.