Bunnings Workshop is under maintenance and read-only.

The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Featured Projects

- >

- Solid computer monitor stand

Solid computer monitor stand

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

A sturdy monitor stand for a large monitor with hidden speakers.

The project

Eighty percent of my job is at home, so having an organised desk that you can be comfortable in front of is important. I also find myself eating lunch at my desk quite a lot and that was an issue with my previous monitor because my legs got in the way of pushing the keyboard forward when I wasn't using it. Cheap stands (quality and cost) can go for as little as $30, while the better looking ones are in the $200+ range. I was looking for something that was both cost efficient and complemented my workspace and habits well, so I decided to make my own.

This is my old desk workplace.

Tools and materials

Tools and materials used in the project:

- Ryobi 2000W 254mm Dual Bevel Sliding Mitre Saw

- Ryobi 18V ONE+ Drill Drive

- Ryobi 19 Piece Metric High Speed Steel Drill Bit Set (9mm used)

- Ryobi One+ 18V Trim Router

- 235 x 19mm 1.8m DAR Pine Premium

- Rocket Fine Sanding Sponge

- Bondall 250ml Monocel Walnut Stain and Varnish

- Fiddly Bits 250g Flat Black Spray Paint

- Monitor Arm of Choice (In my case, a leftover Brateck LDT12-C01).

Steps

Step 1

I had an idea in mind but just needed to know the size I would need. I eventually decided on an 800mm length stand, so I quickly cut a piece of that off and sanded the end and the whole thing for good measure.

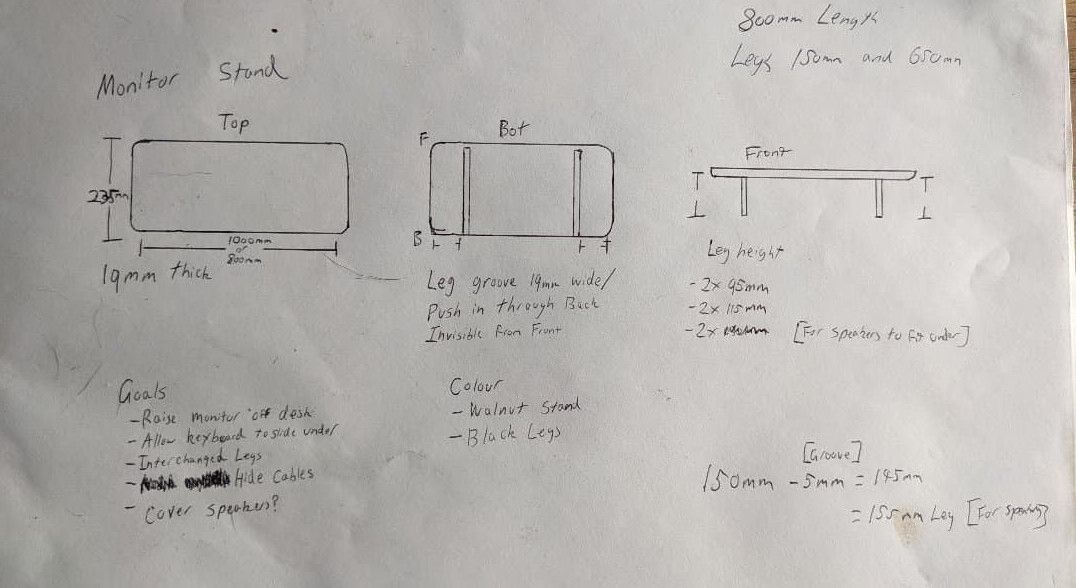

I made a rough sketch of what I wanted to do.

As the legs were only going to be 19mm thick, I cut three rough heights, just so I could see what the stand looked like, so I had 2x 95mm, two x 115mm and two x 165mm.

Step 2

I used the round over bit to create the edges on the front and sides of the stand (in that order), leaving the back flat so it could fit better against the back wall. I also ensured I had a nice little groove along the front. After this, I sanded the thing again.

It helped to use an off-cut of the same wood in line with the wood I was doing the round over on and continued onto the off-cut before ending the router run. That way I didn't end on the corner of the project piece and risk damaging it.

Step 3

I switched over to the 19mm straight bit and created two straight 220mm lines at 5mm deep. These lines were at the 150mm and 650mm of the stand. They stop just before the front, so the legs look "hidden" under the stand and allow the nice, rounded finish of the front to be uninterrupted. The cut straight at the back allows for your legs to simply slide in.

Be sure to measure the distance between the centre of the bit you are using and the router edge. Use an offcut and clamp it down in a straight line along where you want to route to ensure you have a perfectly straight line.

After both were completed, I gave them a light sand to make it smooth.

Step 4

I put the round over bit in and gave all the legs a front sided double round over edge so that they would fit snug in the groove. After this, I cut the ends of each leg so that each were exactly 220mm long (the length of the groove). Each leg was then sanded for a smooth finish.

Step 5

With each leg fitting flush and snug in the grooves, I gave them each a coat of black spray paint. I then got to work staining the top piece with the Walnut Stain and Finish. It took me four coats, lightly sanding between each coat, and letting it dry for six hours at a time before I got the desired colour.

Step 6

With that done, I got to work installing the monitor arm. I used a 9mm drill bit to drill a hole in the centre of the board where the tightening mechanism goes through. Then I placed it all together via the instructions of the monitor arm. I then ensured I had the proper height I needed and that the arm itself was capable of holding the weight of the monitor without drooping.

Step 7

With everything together, it was now just seeing which legs I wanted to use. My original plan with the 165mm legs were for the speakers to go under the wings, but this proved to be way too high. See below.

Eventually, I ended with the 95mm legs and placed the speakers behind the monitor on the stand itself.

The 95mm legs ended up being perfect. The leg spacing is just the right size to fit my keyboard under. It also had the added benefit of covering up a lot more cables than I realised, so the project was a resounding success.

Measuring and taking my time were the true champions of this project. While frustrating at times, especially as this was my first time using a router, the end result has invigorated my want to continue with my office facelift and has improved my general mood.

Also, I can now place my keyboard all the way back and eat my dinner at my desk. It was an interesting project to take on. I was certainly happy that I didn't use any screws either and the thing is solid. Huge success.

How to build a desk

Workshop member Rob (Peggers) has shared a step-by-step guide How to build a desk.

More inspiration for your home office

Experienced community member Nham built large computer desk for his home office for just $150.

Whether you are building a new desk or reinvigorating an existing one, get inspired by the creative Bunnings Workshop community's Top 10 most popular desk projects.

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

No screws? What keeps the legs in place?

The fine work with your router looks perfect.

It looks fantastic and the amount of work you put into the final finish is commendable. It shows in the excellent outcome.

Congratulations. I am inspired to try to make one.

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Hi @TedBear

Let me tag @Remarka6le to make them aware of your kind words and questions. I'm guessing friction and adhesives are holding the legs in place.

Eric

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Hey @TedBear ,

Apologies for the late reply, today is the first day in MONTHS that I've been able to login into workshop. There are 0 screws or adhesives holding them in place, it's entirely friction and it's solid. I originally planned on having brackets hidden on the inside to keep them in place but I opted out so I could interchange the legs with higher / lower pieces as needed.

As of right now, the monitor is holding two speakers, a monitor, the bracket arm itself, a webcam and a keylight and is still solid. Would highly recommend the build if you've got the time.

- Mark as Read

- Mark as New

- Bookmark

- Highlight

- Report Inappropriate Content

Thanks for that clarification @Remarka6le .

I'm even more impressed at your routing skills.

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects