The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Outdoor

- >

- Re: How to build low-level decking?

How to build low-level decking?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to build low-level decking?

I am very much a newbie when it comes to DIY - we only bought our first house in June!.

We have a raised QLD house, all legal height, and underneath the house at the pack is a gravel/soil area.

I am contemplating building a low level deck under the area so that we can walk out there comfortably, and also have an inflatable hot tub & ice bath out there.

Due to the cost, I plan to build it in multiple stages - starting with a 4m by 3m area for the icebath, then following by a 3m x 3m area for the inflatable hot tub, ideally linking the two areas with a small walkway.

I am thinking using the TuffBlocks for the foundation, mainly because they will be on soil, and I plan to add some road base and compact it under each TuffBlock.

I think i would need 2 bearers and 11 joists (including the 2 ends) equally spaced, and I am thinking of using 140 x 45mm timber for the bearers & Joists.

Some questions:

Do i need an additional bearer down the middle, or is a 3m joist span acceptable for a low level deck, given it may have an inflatable hot tub on it?

If i have a bearer down the middle, do i then split the joists into 2 x 1.5m, or do they have to lie on top of the 3 bearers, adding unwanted height?

Does every joist need TuffBlock under them, and so that would mean 3 TuffBlocks per joist... ie: 33 TuffBlocks!??

Do the bearers also need TuffBlocks or do they just sit under the joists?

Trying to keep costs down, and keep it simple, as this is my first decent DIY project.

Any advice welcome before i go too far...

Pictures for context

!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build low-level decking?

Hi @ipeters,

Welcome to the Bunnings Workshop community, it is fantastic to have you with us.

By the sounds of it, you've already got a reasonable understanding of deck building, but I'll add some handy resources just in case -

- How to understand deck components

- How to understand deck span tables

- How to build a deck

- How to build a low-level deck.

I also use the Hyne Bearer Span Table and Hyne Deck Joist Span Tables as a reference when designing decks comprised of H3 MGP10 Pine, like the 140x45 you are proposing to use.

You will note in the joist span table that the maximum single span of 140x45 is 2600mm, so it would not be sufficient for a 3000mm span. Adding in the potential for a hot tub, which will add considerable load to the deck, this would not be ideal.

In this situation, I would suggest adding a third bearer down the centre of the deck and using 140x45 Joist Hangers to attach the joists to the bearers. Using joist hangers means the joists sit in line with the bearers, so there is no additional height added to the deck.

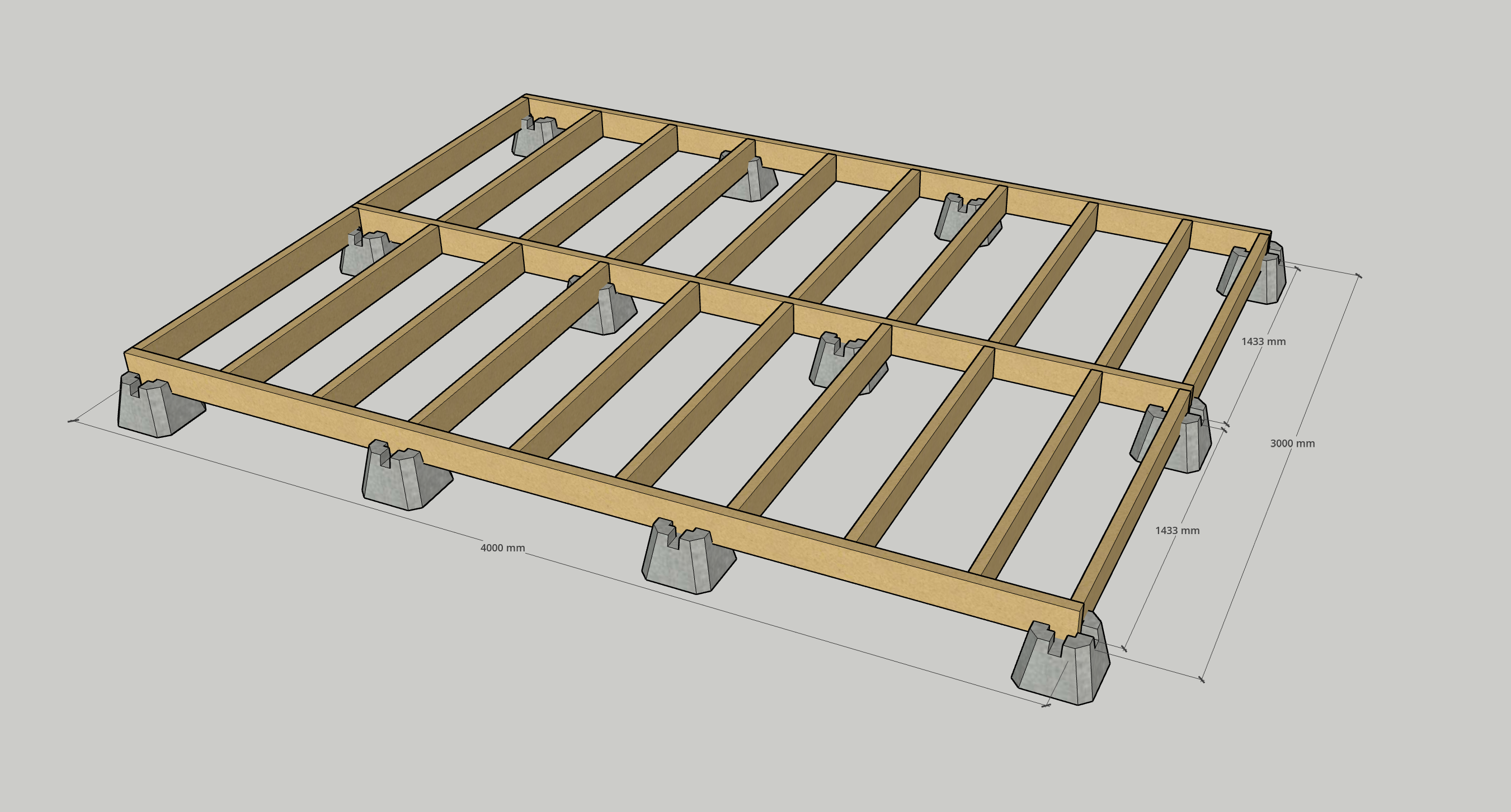

You would end up with a deck frame that looks like this -

You'll note that the tuff blocks only sit under the bearers. If the joists are connected to the bearers using joist hangers, then this becomes a structural connection, and there is no need for them to be supported by tuff blocks.

This would make a very solid deck as the joists are well inside their span limits, but with the inclusion of a hot tub, which will add considerable weight, this would be a good design for your purpose.

Let me know what you think.

Jacob

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build low-level decking?

Thanks Jacob - thats great!

I wouldnt say i have a good grasp.... just been doing lots of googling and using ChatGPT - however that keeps giving me errors i need to correct.

So essentially i cut the joists in two, and connect them to a middle bearer using the joist hangars.

I thought the TuffBlocks needed to be under the joists?

If not, and they can be spaced under the 3 bearers, then thats great as will massively reduce the numbers i need, helping keep costs down!

I would imagine investing in a circular saw for cutting the wood & decking boards would be a sensible idea?

thanks again!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build low-level decking?

Hi @ipeters,

If a joist is connected to a bearer, then it doesn't need to be supported by a block, post or stump. The weight applied to the joists is transferred through the joist hangers into the bearer, which then transfers it into the vertical supports (tuffblocks). There are situations where it's necessary to support the joists with posts or blocks, but your situation doesn't call for it.

You can make all the cuts necessary for a deck using a circular saw and a speed square, but a mitre saw would be a better tool for the vast majority of the work. With a circular saw, there is a bit of a learning curve and some room for error; with a mitre saw, as long as you are measuring accurately, it is pretty hard to mess things up. If you've never worked with a circular saw before, you're going to get a much better result using a mitre saw.

Let me know what you think and if you have further questions, please don't hesitate to ask.

Jacob

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build low-level decking?

Thanks Jacob.

Honestly i didnt know there was more than one type of saw ![]()

This is the sort of thing i was thinking of, which sounds like what you recommend.

Regarding attaching the decking to the frame, i have a drill driver. i assume i just drill screws through the decking into the joists?

I feel like it is all straight forward & logical - just have no practical experience. But have to start somewhere!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build low-level decking?

Hi @ipeters,

The Ozito PXC 36V 2 x 18V 210mm Sliding Compound Mitre Saw would work fine, but being a battery saw, you'd need to make sure you have a few batteries on rotation to ensure it doesn't run out of power when you need it. You could certainly use it, but oftentimes a corded mitre saw is better when there is a power outlet readily available. Unless you had a burning desire for your mitre saw to be mobile, I'd look at a corded option like this Ozito 1800W 210mm 8-1/4" Double Bevel Sliding Mitre Saw SCMS-1621 instead.

The most efficient way to do it is to have a drill with a countersinking drill bit, like this Kango 10G Adjustable Countersink Drill Bit Set, and then an impact driver with the corresponding driver bit for your decking screws. That way, you can drill the pilot holes with your drill, then drive the screw with your impact driver without having to change bits. You can certainly do all the drilling and driving you need with a drill, but you'll have to swap out bits pretty frequently, so it is worth considering grabbing an impact driver as well.

Honestly, decks are about the simplest carpentry you can do, and they really are a great project to learn on. As long as you measure and cut accurately and make sure things are square, everything flows pretty logically, and you start to get a flow going pretty quickly.

Let me know if there is anything else I can assist with and don't hesitate to reach out along the way.

Jacob

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build low-level decking?

Thanks.

I was looking at the battery ones, as i have already have 4 or 5 of the batteries at home for my mower, existing drill etc...

Is the only benefit of using an impact driver, compared to a drill, not having to swap out bits, or is a still not ideal to use a drill for the decking screws?

Just trying to avoid another piece of equipment, but if i will live to regret it then i can put it on the list!

Regarding decking screws, is something like this sensible, and do the same screws get used for attaching the joist hangers?

Sorry, so many questions but so many different screw types!!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build low-level decking?

Hi @ipeters,

I've worked with a few chippies who have battery mitre saws, and they are honestly brilliant, especially when you need to be mobile and power isn't available. As long as you've got plenty of batteries, then there's nothing stopping you.

Not having to swap bits is the main benefit of having both a drill and an impact driver. They are both capable of drilling and driving; the main difference is how they apply torque and how much battery they use for each application. Realistically, if you are predrilling pilot holes, which is a must, you wouldn't even notice the difference.

Those decking screws would be perfect for attaching your decking boards, but they can't be used for joist hangers. The correct screws for attaching joist hangers are these Pryda 12G x 35mm Hex Head Timber Connector Screws.

Please don't hesitate to ask questions. I am more than happy to help out, and I know from experience how confusing it can be.

Jacob

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build low-level decking?

HI Jacob,

Just out of interest, do you think 90 x 45mm would work instead of the 140 x 45mm?

Obviously 140 would give additional support/sturdiness, but is it worth the extra cost?

thanks

Ian

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build low-level decking?

Hi Ian (@ipeters)

Personally, I wouldn't use 90x45 for a few reasons.

90x45 can span 1400mm between bearers when acting as a joist, and 900mm between tuffblocks when acting as a bearer. With a 3-bearer design, like above, you would be ever so slightly over this 1400mm span, so you'd either have to bring the bearers in a little bit or add another bearer. You would also have to add an extra two tuffblocks per bearer. If you did the math and took into account the additional cost of the tuffblocks, you'll likely find that the difference in cost isn't all that much.

The main factor in my thinking, though, is the hot tub. When you consider a cubic metre of water weighs 1000kg, and I'd say a hot tub is going to have at least a cubic metre of water in it, I'd be much more comfortable with that sitting on something that is slightly overengineered.

Let me know what you think.

Jacob

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.