The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Garage and Shed

- >

- Re: oIto mitre saw 254mm

oIto mitre saw 254mm

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

oIto mitre saw 254mm

Hi there

how can I tighten the clamp which I got with my ozito compound mitre saw 254mm .

thanks

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: oIto mitre saw 254mm

Hi @0225556559,

Welcome to the Bunnings Workshop community, it is fantastic to have you with us.

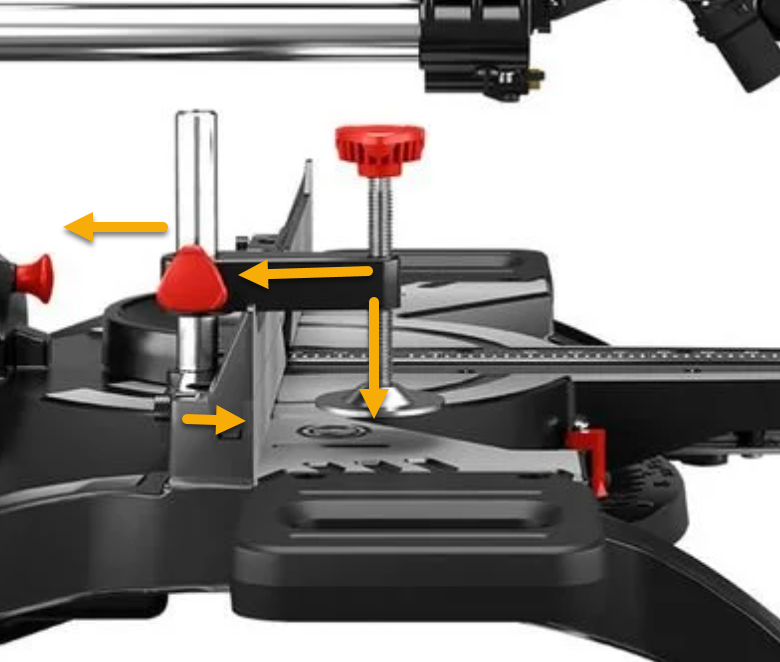

If you are referring to the Ozito 2100W 254mm 10" Corded Double Bevel Sliding Mitre Saw - SCMS-2125, then the clamp is operated using these two knobs.

The one on the left in the above photo allows the black arm to move up and down the cylindrical rod. This is used for spacing the clamp based on the workpiece. It should be adjusted first to get the round plate on the bottom of the clamp close to the workpiece.

The knob on the right is connected to a thread, which, when rotated, will tighten the clamp down on the workpiece.

So, to summarise, use the one on the left first to get things close, then tighten it up and use the one on the right to tighten the clamp down on the workpiece.

If there is another aspect that you are not sure about, please let me know so I can advise further.

Jacob

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: oIto mitre saw 254mm

Thanks for the assist ..

but I have a concern about that if I try to put the cylindrical hollow rod in to the hole which is behind the fence’ there is no tighten mechanism to hold the rod stable !

or is it the way it used to be?

thanks

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: oIto mitre saw 254mm

Hi @0225556559,

The rod is held in place by tension when the clamp is tightened down on the workpiece. When the clamp pushes down on the workpiece, this force will push the black arm backwards towards the cylindrical rod, which will in turn push the top of the rod backwards, and the bottom forwards, which will lock it in place in the slot.

It's a bit difficult to explain in words, but if you put a piece of timber on the mitre saw and tighten the clamp down, you should be able to see/feel what is happening.

The design is so that you can quickly and easily move the clamp from one side of the blade to the other, depending on the direction of the bevel. It's not meant to generate a massive amount of clamping force, just enough to hold the workpiece in place so that it doesn't move while cutting.

Let me know if you have any issues, I can certainly assist further if required.

Jacob

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: oIto mitre saw 254mm

Hi @0225556559

Just to add one small tip to @JacobZ excellent explanation, is to first wind the clamp up about 10mm above the height of the material being cut. This will then keep the amount you need to wind it back down to clamp it into position.

Remember, this will only support the material from movement if the remaining length is also properly supported. So long lengths of timber need to be resting on something like a roller support stand. These a relatively cheap investment for your mitre saw. The stand needs to be placed on a stable level surface with the top of the roller set to the same height as the top of the saw table. Then when cutting long lengths you would rest your hand on the off-cut side so it doesn't fly up on completion of the cut.

And probably the most important thing to do before clamping or making any cut with a mitre saw, is to ensure the material is resting firmly and squarely against the fence. Failing to so so can result in quite a severe kickback to the point that could even break the fence.

Nailbag

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.