The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Outdoor

- >

- Adjustable gate lock

Adjustable gate lock

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Adjustable gate lock

I'm in a part of western Melbourne where the clay swells and contracts all year with varying groundwater, so every house, fence and post in the suburbs slowly but constantly moves up and down, left and right, backwards and forward. I've got a side gate attached to a fence that latches against a house, and the fence and house move differently (different depth studs/posts, probably), so I am constantly adjusting the latching mechanism (three or four times a year). In the attached pic you can see the chiselled out slot I move the metal strike plate up and down in. I've already filed out the hole in the strike plate, giving me about 5mm extra vertical play.

What I'd like is a solution that allows a lot more leeway - up to a few cm in each direction (↔ ↕) without constant need for adjustment .

As an added challenge, I still want to be able to lock it with a lockwood key (ie, same key as the house doors).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Adjustable gate lock

Hello @ErrolHunt

Thank you for sharing your question about your adjustable gate lock.

I understand your frustration with having to adjust your gate lock constantly. I see that you've found a solution for the vertical movement, but now you want the room to move horizontally as well. I suggest making a striker plate receiver out of Metal Mate 40 x 40 x 1.6mm 1m Galvanised Steel Square Tube.

I suggest cutting a length of at least 150mmm and marking one side as the receiver side. Mark the side you wish to cut a hole in. On the opposite side of the steel mark the area where you need to put the screws in. Cut the hole using a Ryobi 800W 125mm Angle Grinder with a compatible Cut Off Wheel.

I recommend painting the steel to protect it from the elements. Position your new receiver and test to make sure it works. I suggest putting in a Pinnacle 200mm Galvanised Coil Gate Spring to keep your door from rattling in strong wind. Please keep us updated, we look forward to seeing your gate lock fixed.

Let me tag our experienced members @r23on and @TedBear for their recommendations.

If you need further assistance, please let us know.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Adjustable gate lock

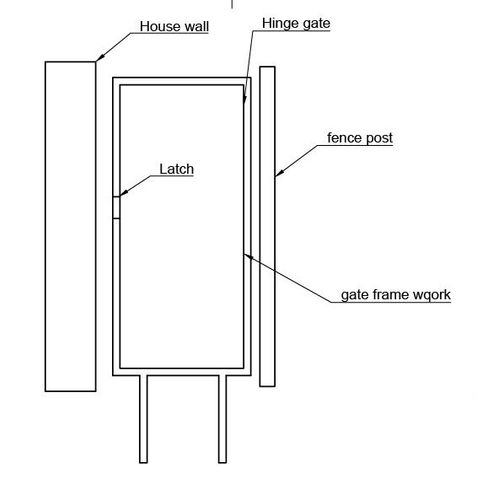

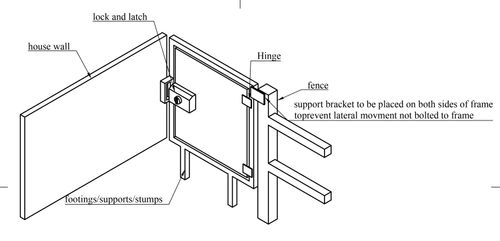

Hi the simplest solution to this problem is that the gate and latch are all part of one frame work. As to where you mount the frame mounted on the house or fence, that decision would be based on the one with the least movement. Either way the frame would float. I take it the gate is a full size for height and width.

So as the frame is structurally sound the material to use 3mm x 50mm x 50mm RHS gal

There is another method which takes a bit more work but it allows all components to float independently (house, gate and fence) that would be to add 2 section of the 50 x 50 x 600mm long to the bottom of the frame work as footings. To cover any gap between the frame work and house / fence make a trim to cover any gaps. a photo of the full gate way would be good. In the mean time I will get on my cad draw up what I am suggesting (Frame work, trim etc)

Currently I am still in Darwin and escaped Vic Dec last year so access to my CAD system is a bit different to what I have at hand here and my thanks go Darwin Mens shed for the use of their version Fusion 360

This is just a sketch to give you the prospective of how the frame work can work and yes it will be a bit more work.

I have not put any sizes to the sketch not knowing any spacings etc

The frame would be made to suite the gate / replacement gate with gate hinged on the frame, the height of the frame is whatever you see fit. The 2 x 600mm sections at the bottom are your footing / stumps /supports

At the top of the frame I would mount brackets on the house and post to provide a level of support to stop forward and backwards movement

Or just make a frame that is bolted to the house. In either method the gate and latch are set in one plan

I look at things for the long term. You have stated the ground in your area is unstable hence the gate lock and latch must be set in the same plan to prevent movement in any direction. If the gate is mounted to the fence post and the latch mounted to the house the problem will still exist as you have two moving plans

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Adjustable gate lock

I think @EricL 's long box idea seems the easiest way out. (But I'm looking forward to seeing @r23on 's drawings too.)

As you are wanting to allow for some play in the horizontal direction, then the bolt will not have anything solid to latch against, so putting the suggested spring on the gate will be essential to minimising on it moving in the wind.

I suggest that you carefully set a gap between the lock and the box, such that the sloped side of the bolt will hit the leading corner of box and be pushed inward, since there is no angled striker plate edge to help push the bolt inwards in this design. If the two are set too close together the bolt is likely to just strike the box too harshly and not be pushed in reliably.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Adjustable gate lock

I have had a bit of time to up date my sketch to give a better prospective as stated the frame can ether be mounted to the house or set to be a stand alone.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Adjustable gate lock

Hello @r23on

What a fantastic suggestion to the constantly moving gate assembly! By making the gate assembly as a whole, it will stay together no matter how much it moves. Let me tag @ErrolHunt so that they are made aware of your recommendation. You could in essence apply this solution to all exterior gates.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Adjustable gate lock

Hi Eric

The solution has been around a long time when you next go from walk check out the number of gate ways that have used this method. You will find most of them are bolted to the wall of the house and moves with the house. It should never be bolted to a fence as the fence moves too much. Hence a trim can be made to match any gap be it on the fence or on the house. Plus if look closely at them they have used 13mm RHS which is not really stable for long term. that’s why I suggested 50mm x 50mm RHS even 30mm x 30mm is good

have a great day

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.