The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Outdoor

- >

- Re: Building small low-level composite d...

Building small low-level composite deck on concrete and soil

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Building small low-level composite deck on concrete and soil

Hi guys.

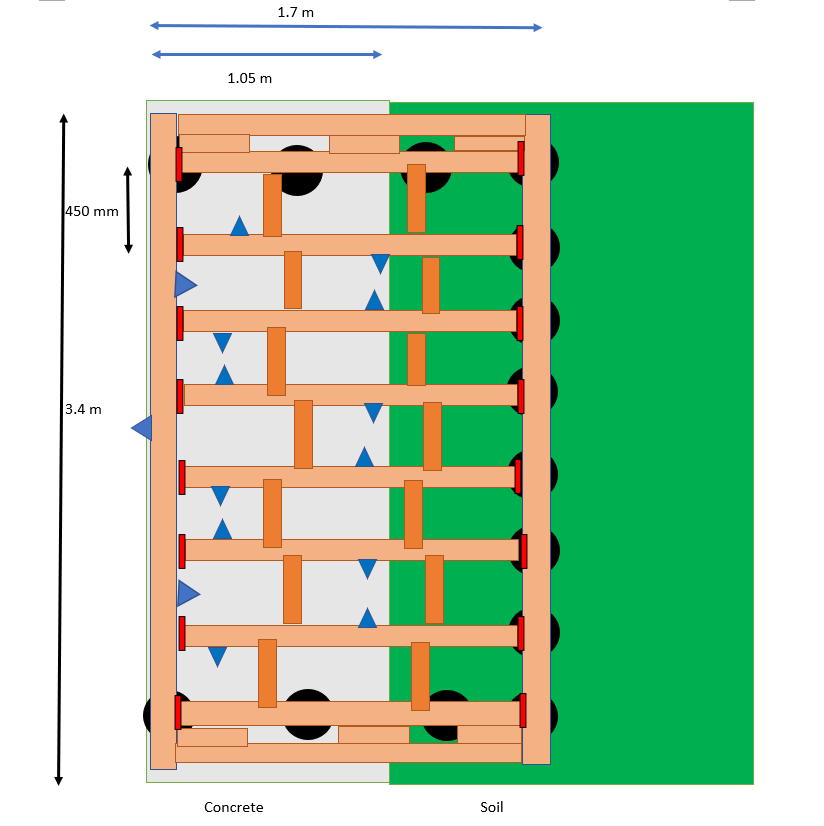

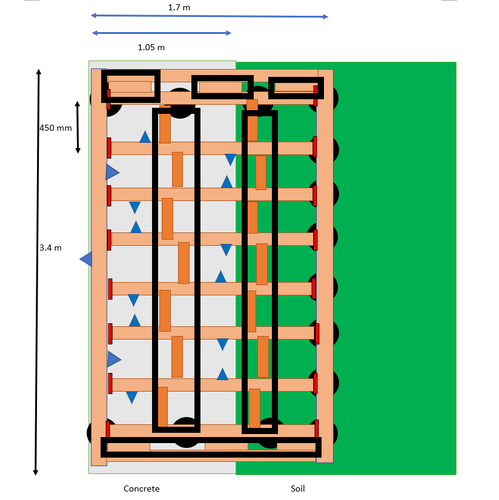

I will be starting to build a small low-level composite deck in my backyard very soon. The deck size is about 3.4 m x 1.7 m, in which a larger part of it stands on the concrete whereas the outer part stands on the garden as illustrated on the image below. I have read through oninpena's Low-level composite deck (which is quite similar to my project), Jithesh's low-level deck with picture framing and low-level deck on concrete slab and Adam_W's How-to-build-a-low-level-deck. These posts/threads are very inspiring and has provided me with fundamental knowledge of building a basic deck and numerous practical tips.

Black dot = Tuff block or minifoot pedestal? (Difference?)

Blue triangle = Angle/L Bracket

Orange rectangle = noggins (required?)

Red rectangle = Pryda Joist hanger

I will be using 90 x 45 mm treated pine for substructure and Ekodeck composite decking in my project. Can anyone review this diagram and enlighten me if it's structurally sound? What are the difference between the tuff block and minifott pedestal? I realise that I will probably need this due to potentially uneven surface going from the concrete to the grass area (I will be putting pavers and concrete on the soil). Would the amount of tuff block in the picture be adequate in supporting my small deck?

I will also be using L-bracket to support the deck off-ground on the concrete. I do not actually have any limits on the height because the deck is not actually going to connect to any door entrance, so what would be the ideal height above ground to provide adequate air circulation and avoid moisture retention. Is the number of L-brackets and noggings in the diagram adequate? The spacing between the L- brackets on the joist is probably about 0.5-0.85 m. I have seen 1 m spacing was suggested in other threads so I presume there was no harm going any lower than 1 m if my deck is small. Not sure if noggings are required in this small little deck?

I have also notice many have used double joists on the 2 sides of decks, so I have included that into my diagram. Just wondering if the double joist at both ends makes it more structurally rigid or is it just for laying the frame/fascia on top of it? Any insights from anybody is much appreciated.

Thank you

Regards

Sky

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Building small low-level composite deck on concrete and soil

Hello @SkyL93

Welcome to the Bunnings Workshop community. It's wonderful to have you join us, and thank you for sharing your questions about building your low-level deck.

It's fantastic that you've gotten a lot of information from the projects shared by our members. Looking at your proposed decking frame, it looks very well supported. Let me try to answer some of your questions.

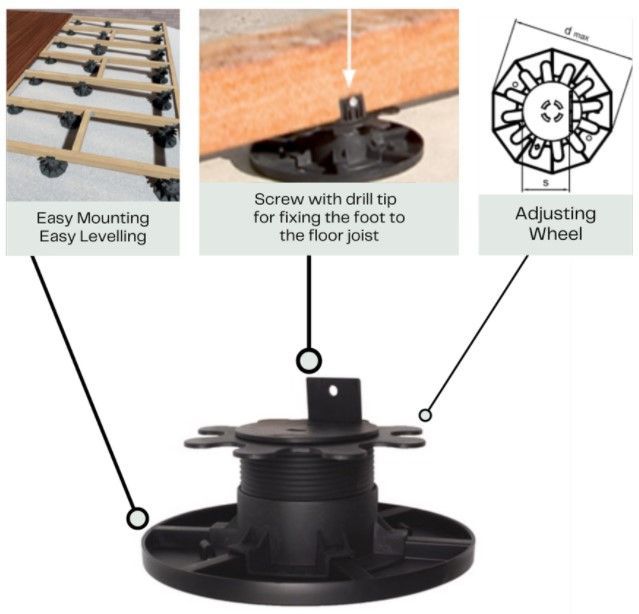

- The TuffBlock 300 x 300 x 90mm Instant Foundation System Deck Support is an alternative footing for your decking. You can either have the deck frame on top of the foot or use a post to meet up with your required decking height. The Builders Edge 35 - 60mm Smallfoot Pedestal Feet is a height-adjustable deck footing. There is no need to add timber or shims, simply turn the adjusting wheel to change the height. Have a look at the photo I've placed below.

- The number of footings you've placed in your design is adequate enough to hold the frame.

- The two things to keep in mind when deciding on the height of your deck are airflow and water drainage. If the deck is too low you'll not get ventilation flowing through which is detrimental to your timber frame. Although it will not affect your composite decking, it will affect your natural timber frame. Putting weed mat and gravel to help facilitate drainage is a must. Having good drainage will ensure that you won't get any pooling water under the deck.

- Having the "L" brackets spaced less than 1 meter is ok. The more brackets you have the more support you have. Having the noggins makes the frame stiffer and adds structural rigidity.

- The double joists at the end of the frame are used for "picture framing". Have a look at the - Low-level Merbau deck over concrete slab by @Neo19. You'll notice that the deck has an outer "picture frame" and the decking panels are laid inside this frame. When compared to an ordinary deck that has the deck panel ends exposed. It makes the deck look neat and professionally built.

I suggest visiting your local store and having a look at the deck footings. Take one out to the timber yard and test it out to see for yourself how big the gap actually is. My number one tip for your project is to make a detailed list of the materials you'll be using for your deck. Speak to the timber specialist when it comes to timber lengths and quantity.

Please keep us updated with your progress, we look forward to seeing the start of your low-level decking project.

If you need further assistance, please let us know.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Building small low-level composite deck on concrete and soil

Thanks for the reply Eric.

Just to clarify as I am really new to this

1. Are the noggings and timbers in the middle of joist as pictured in this diagram are all offcuts from timber (treated pine in my case)? Do you just join them together using timber screws, like the Pryda Timber Connector Screw ?

2. I checked Bunnings website and noticed that the 90 x 45mm L/M Outdoor Framing MGP10 H3 Treated Pine (I/N 8032162) does not specify a length . Does anyone know what length do they come in? Also if it's too short to span the entire length of my outer frame and if I need a couple, do I just join them in the middle ?

3. I have noticed window packers being used in some other threads and just wondering what are these packers used for ?

Thank you

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Building small low-level composite deck on concrete and soil

Hi @SkyL93

Yes, the timber pieces can be classified as offcuts. However, these pieces are often cut to size so that they fit between the joists. It is recommended to use galvanized or coated screws. These screws are purpose-built for decking as they are made to withstand exposure to timber chemicals and inclement weather. But the Pryda screws should work as well. The 90 x 45 come in several sizes from 1.8, 2.1, 2.4, 2.7, 3.0, 3.6, 4.2, 4.8, to 5.4. Please note that not all lengths are available at the store and may need to be specially ordered. It's best to discuss your timber length needs with the timber specialist at your store. The window packers are used as spacers between the floor and timber frame. It's often used when you need to increase the gap in small increments.

If you need further assistance, please let us know.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Building small low-level composite deck on concrete and soil

Thanks.

Currently I am compiling the materials I need from Bunnings

Just want to check for the following materials

1. If going for a galvanised timber screws, which particular timber screws from Bunnings do you recommend for my 90x45 treated pine frame. I tried to browse through Bunnings website and it seems like they come in different sizes and heads, which can be very confusing. What do you recommend in my case?

2. Planning to get the following to join the frame,

- Dunnings 40 x 80 x 40 x 5mm M12 Galvanised Angle Bracket

- Ramset 12 x 60mm Galvanised DynaBolt Plus Hex Nut Bolt

Can you let me know if these are suitable options for stabilising the timber onto the concrete ?

Thanks

Sky

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Building small low-level composite deck on concrete and soil

Hi @SkyL93,

I'd recommend 125mm galvanised bugle screws. That gives you 45mm for the frame thickness and then a decent 80mm into the end of the other timber. You'll need to pre-drill your timber with a 4mm drill bit to ensure it doesn't split.

Those brackets and Dynabolts will work, but you'll also need a bolt to attach the timber to the angle bracket.

Please let us know if you have further questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Building small low-level composite deck on concrete and soil

Thank you Mitchell

I have always thought the timbers screws will be used to attach the timber to the angle bracket, but it seems it is used solely for timber to timber ?

Also, I have a Makita brushless hammer drill and impact driver (DHP 485 and DTD 153), can i use them to do the jobs?

Thank you

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Building small low-level composite deck on concrete and soil

Those brackets have large holes in them and most screw heads will pass straight through. You could potentially use a coach screw and a washer, though bolting is the preferred method.

That drill and driver will be suitable. Since you are using a cordless hammer drill you can expect the 14 holes in the concrete to take a while. You'll get there, but not as quickly as if you were to use a 240v hammer drill. I'd recommend giving the concrete holes a shot with the cordless drill. If they are taking too long then it might be worth picking up a cheapish XU1 500W 13mm Hammer Drill.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Building small low-level composite deck on concrete and soil

Hi guys

I have compiled a material list for the composite deck

Items | Item Number | Quantity | Cost | Total Cost |

Substructure | ||||

Treated Pine 90 mm x 45 mm x 3.6 m | 8032162 | 2 |

|

|

Treated Pine 90 mm x 45 mm x 1.8 m | 8032162 | 16 |

|

|

Pryda Joist Hanger Suits 45 x 90 mm | 1071668 | 16 | $1.80 |

|

Pryda Timber Connector Screw 12 x 35 Hex Head Pack 50 (to attach joist hanger) | 0084754 | 1-2 (?) | $15.50 |

|

Builder’s Edge 25-40 mm Minifoot Pedestal Feet | 2450073 | 14 | $8.40 |

|

Dunnings 40 x 80 x 40 x 5mm M12 Galvanised Angle Bracket | 1070088 | 15 | $2.82 |

|

Ramset 12 x 60mm Galvanised DynaBolt Plus Hex Nut Bolt (to attach angle bracket to the concrete ground) | 2262268 | ? | 1.95 |

|

Zenith M10 x 60 mm Hot Dipped Galvanished Cup Head Bolt and Nut (to attach angle bracket to timber) | 2443482 | ? | 1.11 |

|

Zenith 14 - 10 x 125mm Galvanised Bugle Head Batten Timber Screws - 50 Pack (to attach timber to timber) | 2420698 | 1-2 | $23.00 |

|

Composite Decks | ||||

137 x 23 mm 5.4 m Decking Alpine Ash/Ironwood Composite Ekodeck Designer | 0109384 | ? | $90 |

|

Ekodeck 100 m Pack Quickfix Concealed Kit – To Suit Timber Joist | 0089490 | 1 | $99 |

|

137 x 23 mm 5.4m Decking Alpine Ash Composite Ekodeck Designer Edge Board | 0200710 | 2 | $116 |

|

Could you let me know if there's is anything required missing? I know I haven't account for the drill and circular saw etc.

Also a few questions from me

1. I am not so sure about the number of ekodeck boards that I need ? What's the spacing in between each board? As I only need 3.4 m out of the 5.4 m full length, Is that possible to join 2 shorter 1.7 m +1.7 m to save some cost ?

2. What's the difference in the composite decking board and edge board ? Can I use normal decking board as the edge board or it wont attach ?

3. For the Dunnnigs 40 x 80 x 40 x 5 mm M12 Galvanised Angle Bracket (I/N:1070088 ), just want to confirm that I will need to attach the 2 holes side on the timber with Galvanished Cup Head Bolt and Nut and the 1 hole side on the ground right with dynabolt right?

4. Would also like to confirm that to place the pedestal feet on the soil ground, I will need lay a paver on an even soil ground, then put the pedestal feet on the paver, and gravels around the feet on the paver ?

Thank you

Sky

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Building small low-level composite deck on concrete and soil

Hi @SkyL93,

Great work putting your materials list together. It appears comprehensive.

You'll find this Ekodeck Composite Decking Calculator useful for determining the quantity of decking needed for your project. The minimum gap between edge to edge boards is 6mm. You can use two shorter lengths to achieve your span. A breaker board between them that runs perpendicular achieves a clean look and becomes a feature.

Standard Ekodeck boards have a slot in their edge to conceal your fixings. The edge boards have a rebate allowing a clean fascia board installation. The edge boards are perfect for framing around your decking boards.

One cuphead bolt in the timber and one Dynabolt in the concrete is adequate for the Dunnings 40 x 80 x 40 x 5mm M12 Galvanised Angle Bracket.

A paver is placed on compacted ground, and the pedestal foot goes on top of it. Drainage gravel is placed under the deck to allow water to flow through it.

Here's the Ekodeck installation guide and QuickFix installation guide to read through. I'm sure you'll find them useful.

Please let me know if you have further questions.

Mitchell

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.