Bunnings Workshop is under maintenance and read-only.

The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Outdoor

- >

- How to replace eaves?

How to replace eaves?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to replace eaves?

Hi,

I've had these eaves tested and confirmed they are asbestos. I have a company ready to remove them but I am curious how hard it will be for me to replace them?

For context, the is a concealed gutter system on the house.

Appreicate it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Eave Replacement

Hi @Anthony068,

Welcome to the Bunnings Workshop community, it is fantastic to have you with us.

It would be difficult to say with 100% certainty how challenging it would be without seeing the framing, which ultimately you won't be able to do until they've been removed. Installing soffit sheeting once the framing is complete is usually pretty simple, but you'll have to see what the framing is like to be sure.

The basic process is to cut them to size, lift them in place and fix them off using clouts, then conceal the joins with PVC joiners. The whole process, as well as details about joins and finishing can be found in the James Hardie Eaves and Soffits Technical Specifications.

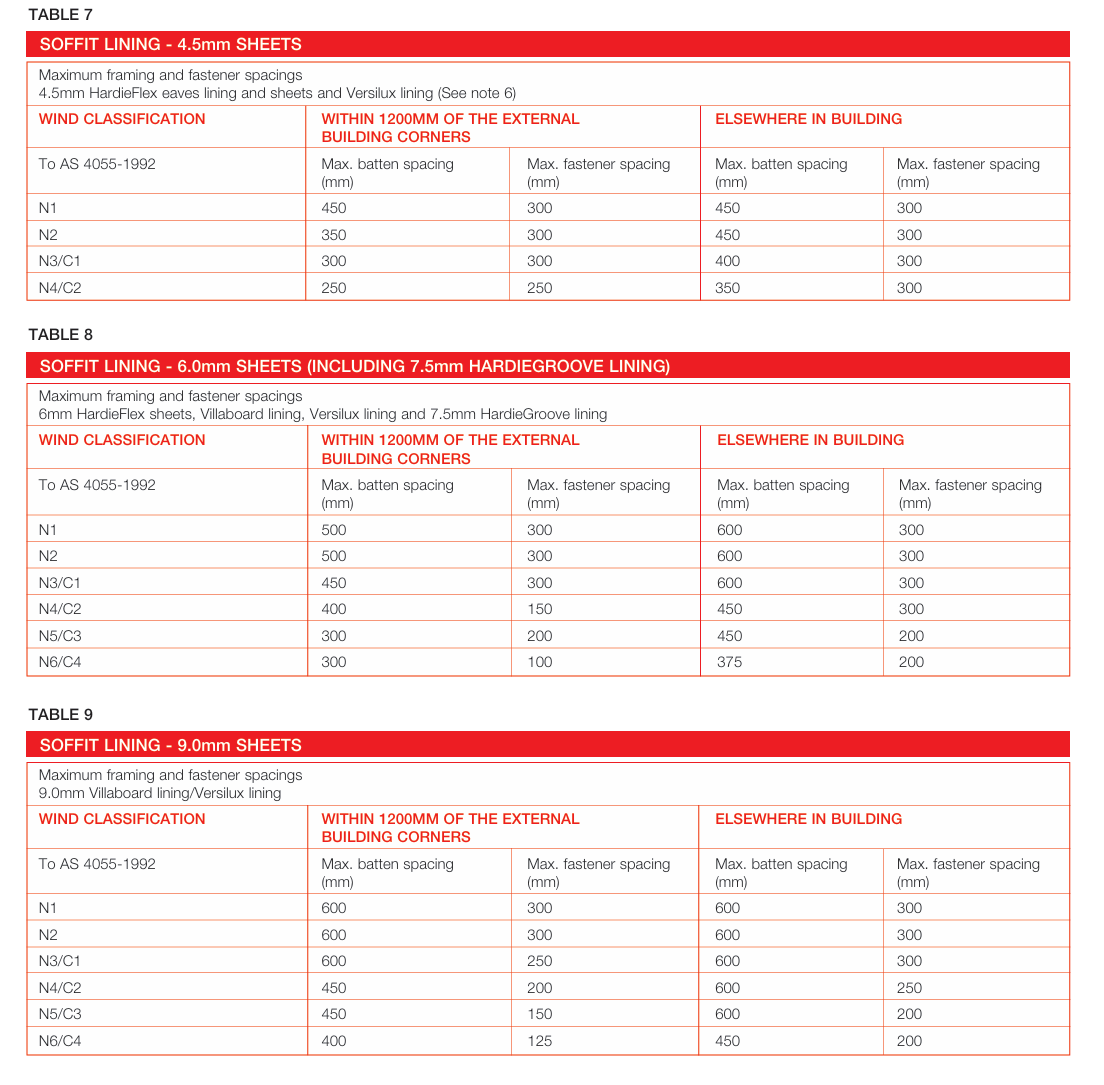

The first thing you'll want to do is assess the framing to see if anything needs to be repaired or replaced. You should also check the spacing of the framing, as different thicknesses of eave linings require different spacing. For example, 4.5mm HardieFlex needs battens to be no more than 450mm apart, whereas 6mm HardieFlex can span 500mm between battens within 1200mm of the external building corners and 600mm elsewhere in the building. Information on this, can be found in the James Hardie Eaves and Soffits Technical Specifications

Once the framing is ready and you've selected your materials, you can cut them to size using a score and snap knife or some fibre cement shears.

There can sometimes be a slot in the back of the fascia board that the sheet will sit inside of. If your fascia has one of these, the sheet must sit in this slot.

Once the sheet is in position, use a hammer to nail in your clouts based on the fastener spacing in the table above. While you are nailing the sheets in place, ensure you slip the ends into the PVC joiners as you go.

Having done it quite a few times myself, it can be a bit daunting to get started, but once you get going, it is pretty easy. It can also be done without a single power tool, which is great for the budget if you don't have any.

Let me know what you think, and if you have any further questions, please don't hesitate to ask.

Jacob

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.