The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Outdoor

- >

- Re: DIY Air conditioner cover

DIY Air conditioner cover

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

DIY Air conditioner cover

Hi all, long time, no post!

Inspired by the many air conditioner covers found in this thread My partner and I decided to give it a crack and make our own.

We recently had our apartment's HVAC system upgraded from a single-head Rinnai split system to a multi-head MHI system purchased from Bunnings Armadale and installed by Short Airconditioning Services.

The idea I had in mind was to not only incorporate a benchtop into the design, but to also incorporate storage as well, to allow us to store things such as charcoals for a barbeque/smoker and an induction cooker for cooking hot-pot. The unit also had to be moveable as if we needed to get the aircon serviced, we need to allow the HVAC tech to easily get to the unit.

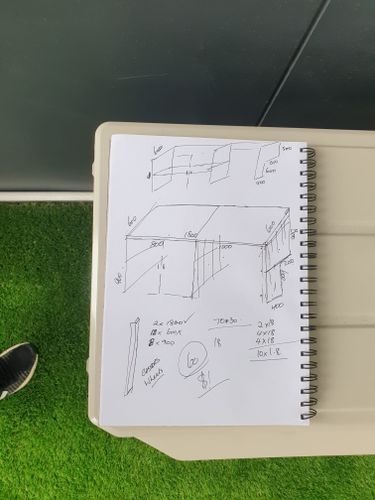

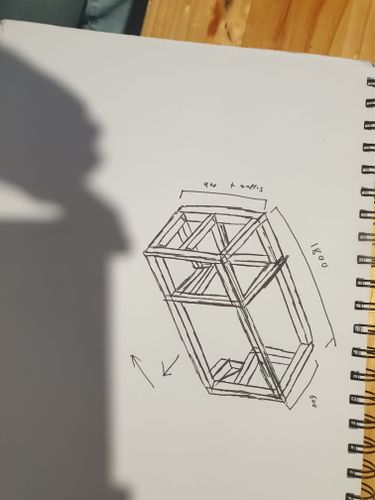

So with that i mind @hazesnow and I came up with these very, very rough plans. The first one is a general idea for the volumes, lengths and such for the timber we were going to use, and the latter was the design for the framing itself. The idea being is that the RHS of the frame needed to clear the huge stack of copper pipes and control cables.

So our frames were made from lengths of H3 treated framing timber. We purchased 5.4m lengths that were cut into 1800mm lengths to make it easy to move them in. These were cut on my stepdad's old Black and Decker Workmate bench, using a Zetsaw saw guide and a Zetsaw Japanese Kataba saw. We used a Kreg pocket hole jig to drill three holes in each piece, and secured the joints using Gorilla wood glue. This first frame is 580x850mm in overall size.

To fit the shelf slats, we used another piece of H3 timber, only this time we cut into it by half the material's thickness to allow it to sit into the side of the frame. That cut is 35mm across the grain and 75mm with the grain. The parallel grain cuts were immensely difficult but we did manage to get them cut out. Once again, all done with the Japanese saw.

We then used the Kreg drill bit to counterbore two screw holes and used 40mm galvanised self-drilling screws to secure the timber pieces together. We used a Makita impact driver to drive these in... Which was pretty loud but it saved us the hassle of potentially stripped screw heads.

This is the completed frame. We built two identical copies of these.

As for the RHS leg, this is how it turned out. This was essentially made to allow for clearance of all the copper pipes and control lines.

To assemble the first frame, we also only had two of these Kwik-grip clamps on hand, so essentially we had to use them... ingeniously. One is acting as a rest whilst the other is preventing the top brace from sliding out of place. We opted to use a scrap piece of 45x75mm pine DAR, cut into two lengths to give us a little more "meat" when it came to securing the top on.

This here gives you an idea as to how little space we're working with here. The whole balcony is only four meters by three meters (approx) in size and most of that space is taken up by the coffee table and by the two outdoor sofas. This is also why we need the frame to be manouverable. This is already starting to get pretty heavy duty!

And this is the left-hand side of the frame completed! In the background are 70x 900x75x19mm hardwood timber pickets (I think they're either Jarrah or Boxwood?) that we picked up for an absolute steal due to the fact that they were a deleted item. They proved to be more than enough to complete the job, so i've got plenty for future projects.

And this is the completed frame! As you can see, there's plenty of clearance around the unit to allow it to clear the AC unit at its current height, but we will be adding wheels to allow it to move around the balcony.

Our top of choice was an 1800x600x26mm SpecRite FJ pine panel. Now I absolutely love these panels due to their versatility. we've used these to put together our coffee tables, my desk, and the benchtop that @hazesnow and I built together. There was no need to cut this panel seeing as it was the exact right size to suit our frame (although, I did end up messing up the width of the frame by about 20mm, but that's absolutely something I can fix with DAR mouldings.)

Now, onto the arduous and very noisy task of getting slats attached to the frame! These were attached to the back using counter-drilled holes in the back of the frame and secured with those same 40mm galvanised timber screws using our impact driver. Now, of course this didn't entirely go without a hitch, some of our pieces did split a little bit, but these split pieces weren't so bad that we had to remove them entirely. The splitting happened in the earlier slats, and only because some of the holes were a little too close to the edges of the timber, but we fixed these splits with some gorilla glue mixed with some of the slat sawdust, and filled the gaps nicely. The rest of the slats, we took extra care to ensure splitting didn't occur.

As for the paint on the frame, we primed the frame with two coats of Dulux 1 step prep primer sealer undercoat, and then rolled on some Low Sheen Dulux Weathershield in Domino to match the wall and help it blend in. Cutting those back few slats was also a major pain... Hardwoods will be the death of me, but darned if they ever look nice when finished.

The shelf slats were cut to size and secured to the cabinet with screws going through the top. I know, nowhere near as pretty, but it definitely made the install a lot easier.

We decided to go with a multi-stage finishing process. Firstly we soaked the wood with Cabot's Cabothane water-based varnish and let it cure, and then applied a marine-grade gloss varnish over the top to protect the lower layers from UV Rays and the elements. Same goes for the top too.

We then added these heavy-duty 100mm castor wheels in the middle and rear of the unit, and added fixed castors on the front of the same kind. This gives the cover plenty of free movement.

Now, the only thing we have left to do is to add a covering slat to the top of the frame, and add two DAR strips to either end to correct for the overall width of the unit. I'll post pics of this later ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: DIY Air conditioner cover

Looks absolutely awesome a such a stellar effort by the both of you. One super proud mumma bear here! @oheyitsbeano You have a real talent for this stuff!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: DIY Air conditioner cover

Hello @oheyitsbeano

Thank you so much for sharing your photos and plans for that air conditioning cover project. It looks fantastic and hides the unit really well. It's great to see that you've placed wheels and added shelves to your assembly adding structural strength and practicality to the unit. I'm sure it will provide you with a long service life.

We look forward to seeing your next project.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: DIY Air conditioner cover

Looks fantastic well done, I've got 3 I've been meaning to do for years would you like to come around and do mine next? I've got beer !!!!!!

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.