The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Outdoor

- >

- Re: How to build low-floating deck using...

How to build low-floating deck using pedestal feet?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to build low-floating deck using pedestal feet?

Hi everyone,

I’m planning to build a low, free-standing deck and would appreciate some advice before I start.

Deck details:

- Dimensions: 7000mm (L) × 1530mm (W)

- Height: approx. 230mm from ground to finished deck surface

- Decking: Ekodeck 140mm × 23mm

- Free-standing: I prefer not to attach anything to the brick veneer

Proposed structure:

- Using plastic pedestal supports instead of posts/stirrups in the ground (to avoid digging and concreting).

- Two rows of double 90mm bearers, running the 7m length: one near the house, one near the front edge.

- 90×45 joists sitting on top of the bearers (not flush), spanning the 1530mm width.

- Approx. 250mm overhang past the front bearer to hide pedestals behind the fascia board.

- I chose bearers because it seems easier to level two rows of bearers rather than levelling 15–17 separate joists on pedestals.

- I prefer joists on top of bearers so I don’t need to use joist hangers.

Questions:

1. The Builders Edge Pedestal Feet products (eg. Smallfoot) seem marketed to support joists only.

- Can they support double 90mm bearers (ie. 2/90x45) instead?

- If not, would TuffBlock work better?

- If using TuffBlock, is the correct method to insert a short 90×90 post section into the block and cut to height?

2. When looking at bearer span tables, most rated sizes appear to be double bearers.

- Does a deck like mine require double bearers?

- Or can I use single bearers on pedestals?

3. Because this will be a floating deck on pedestal feet, do I need to consider lateral movement?

- How do I ensure the deck doesn’t shift over time without fastening to the house or concreting posts?

4. Will this configuration meet minimum ground clearance requirements for composite decking?

5. Any concerns or better suggestions for the structure described above?

6. For Ekodeck fixing, should I use the 3mm or 6mm Quickfix clips for this layout?

Plan and reference photo attached.

Any advice would be greatly appreciated, thank you!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Advice on Low Floating Deck Using Pedestal Feet

Hi @simont,

Thank you for your questions about a low-level deck project at your home.

Unfortunately, the Builders Edge 35 - 60mm Smallfoot Pedestal Feet can only support a single bearer as the top face of the pedestal is 57mm wide. In saying this, there is no need for a double bearer in your situation. I use our supplier for H3 framing, Hyne Timber's Bearer Span Table and Joist Span Table when designing decks, as that is the timber that you will be using.

If you were to use the small pedestal feet with a single 90x45 bearer, according to the bearer span table, you would need to space the feet at no more than 900mm apart on each bearer, meaning you would need 8 per bearer, 16 total. With the cantilever, your joists are within the maximum 1400mm joist span.

As long as you have a well-compacted, stable base for the pedestal feet to sit on, you shouldn't have to worry about lateral forces too much. An easy way to help hold your deck in place is to drive a couple of star pickets into the ground so the top of the picket is below the top of the frame, and then fix the frame to them. Once the decking boards are on, you won't even know they are there.

You meet the ground clearance requirements for Ekodeck, which are a minimum ground clearance (with adequate drainage) of 40mm or a minimum ground clearance (without adequate drainage) of 90mm to the bottom of the board.

I think the 3mm clips would work better. You will have 11 boards at 1507mm total width, with 30mm worth of gaps between them, totalling 1537mm. So, you still have to account for that 7mm somewhere, but it is much better than the alternative with the 6mm gaps, where you would end up with a 37mm discrepancy. You could just increase the width of the deck to 1537mm if you wanted to, or rip one of the boards down ever so slightly.

While you will avoid using joist hangers by having a two-tiered deck system, you still need to fix the joists to the bearers with Pryda Joist Straps 162mm and either Pryda Timber Connector Nails or Pryda Timber Connector Screws. These will fix the joists to the bearers in a way that will prevent the joists from rolling.

I think you are well on the way to a solid deck. With the couple of things I've mentioned above, I think you're pretty much good to go.

Let me know if you have any further questions.

Jacob

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Advice on Low Floating Deck Using Pedestal Feet

Thanks @JacobZ , appreciate the response and advice.

That’s interesting, most (if not all) bearer span table I’ve checked specifies double bearers.

Couple of follow-up questions:

1. Length of bearer: Since 90×45 doesn’t come in a 7.0 m single piece, what’s the best way to achieve the full length ?

2. Pedestal base: Should the pedestal feet sit directly on compacted ground, or do I also need pavers underneath ?

Thank you!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build low-floating deck using pedestal feet?

Hi @simont,

You want to make sure the span table you are looking at is specific to the timber and the grading of timber that you are using. As Hyne is our supplier for H3 MGP10 pine framing, those are the tables I use, and they do not call for double bearers, so there's no need to add them.

You can use a half lap joint and a knuckle plate to join the timber over the top of a pedestal. Check out my first response on page 2 of the discussion How to build low-lying deck over concrete and lawn where I've added instructions and a render.

The pedestal feet should sit on top of a paver that sits on a compacted base. Use around a 50mm layer of road base, compact and flatten it with a tamper, then lay a paver on top.

Let me know if you have any further questions.

Jacob

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build low-floating deck using pedestal feet?

Thanks @JacobZ

I’ll be purchasing the timber from Bunnings, so I’ll refer to the Hyne bearer span tables as you suggested.

Some follow-ups questions:

1. Paver base: For the pavers under the pedestal feet, do they need to be set in mortar, or is that unnecessary?

2. Joining timber: Instead of a half-lap joint and knuckle plate, can I butt-join the two 90×45 bearers directly over a pedestal, and then laminate that joint with an additional length (say, 400mm) of 90×45 on the side? (Effectively a plated butt joint, supported directly underneath.)

3. Pedestal support spacing: I understand from the Hyne tables that the bearers require supports at a maximum of 900mm spacing. However, the Builders Edge technical data (snippet below) recommends a maximum of 750mm between pedestals (noting that the technical data only lists this for joists, it does not have any table for bearers). This confuses me a bit, shouldn’t bearer supports be equal to or closer than joist supports? Should I follow the Hyne bearer span (= support spacing max 900mm), the Builders Edge (=support spacing max 750mm)?

Thanks again for your help, your guidance has been incredibly useful.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build low-floating deck using pedestal feet?

The pavers under the pedestal feet don’t need to be set in mortar @simont. Just place them on well-compacted ground to provide a stable base.

For your bearer joins, yes, you can butt-join the two 90×45 members directly over a pedestal and then fix an additional 400mm length to the side as a plate. It’s not quite as neat as a half-lap joint, but it will work fine as long as the joint is well supported underneath.

As for spacing, the difference comes down to load capacity. The Hyne span tables refer to standard construction where bearers are supported by posts concreted into the ground, which can be spaced up to 900mm apart. The Builders Edge data refers to pedestal systems, which have a lower load capacity, so the supports need to be closer together; typically every 750mm.

So in this case, follow the Builders Edge recommendation and space your pedestals no more than 750mm apart to ensure proper support.

Please let me know if you have any questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build low-floating deck using pedestal feet?

Thank you @MitchellMc.

One more question, if I may, which is something I haven’t quite been able to solve for.

Since the deck will be approximately 230mm high, I like to finish the exposed vertical front edge with two rows of decking boards to create a neat fascia/skirted look.

What’s the best way to design the subframe so that it can properly support those vertical boards? Whilst the first row could be fixed to the rim joist, how do I fix the second row?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build low-floating deck using pedestal feet?

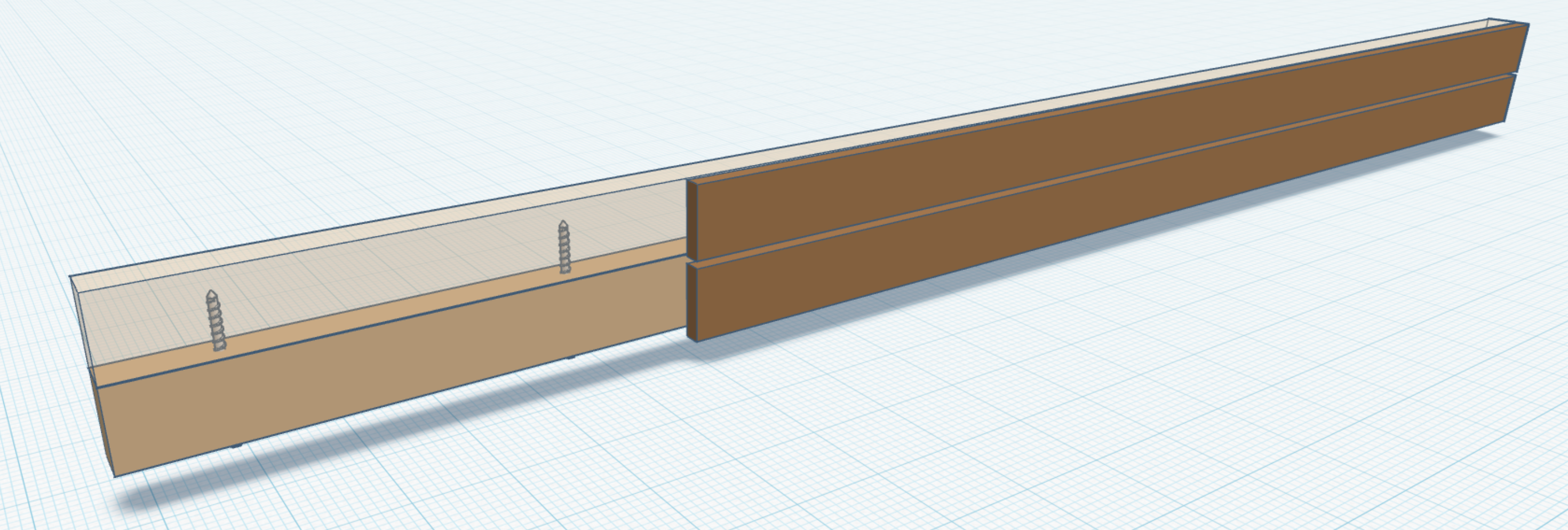

For the rim joist on that side, before installation, I would connect a second 90 x 45mm on its edge @simont. Use timber bugle screws to hold them together, as shown in the rendering I've created below.

Mitchell

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.