The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Outdoor

- >

- Re: How to build outdoor dining furnitur...

How to build outdoor dining furniture?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to build outdoor dining furniture?

Hey Folks

Just looking to get some feedback/ideas on a DIY 10 seater for our new deck.

I'm thinking of using 50x50 pool fencing for the legs, cut down to about 700mm height, capped off on the bottom so not to damage the flooring. Looking to make up a rectangular frame with steel to sit atop the legs. 2400mm long with 2 inner rails spanning the same distance with a couple of cross pieces to stiffen it up.

Currently thinking of using left over ekodeck boards I have from the deck project to act as a table top / inlay. The looking im going for is a butt joint "picture frame" using the steel framing with the ekodeck boards inlayed and to finish flush along the top with the frame

my questions -

- What profile steel framing should I use for the top?

- Any spanning considerations I need to think of?

- I have a mig welder at home - though not overly skilled with it, what advice could I get regarding joining/fixing everything together?

Also any general advice or thoughts to consider - I have found myself with a few weeks of leave and would love to knock out this during this time

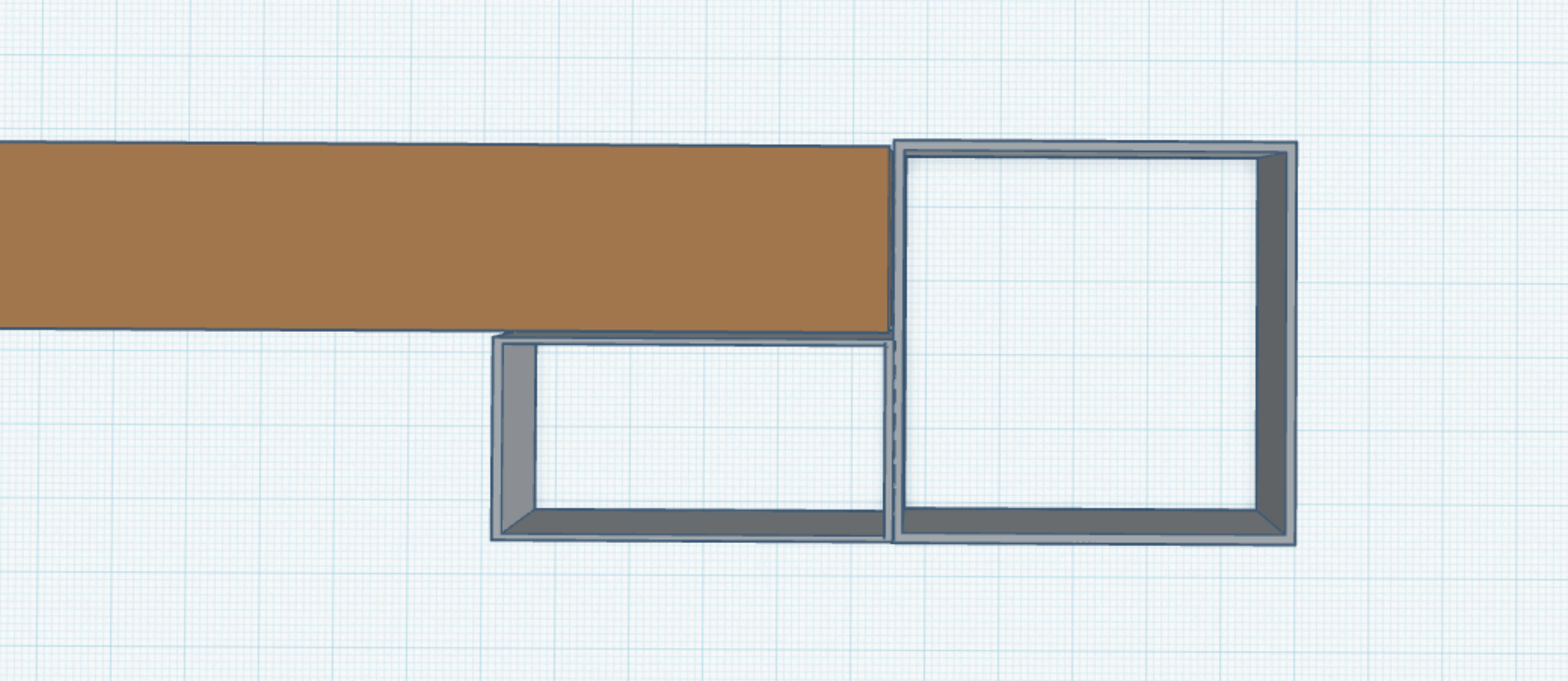

current proposed plan attached

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build outdoor dining furniture?

Hi @Halima,

It sounds like you have a solid starting plan and some great materials to work with. For the steel frame, a common approach for a table this size is to use 50 x 25 mm or 50 x 50 mm rectangular hollow section (RHS) steel. This gives a good balance between strength and weight and will easily support a 2400 mm long tabletop with the inner rails and cross pieces you’ve planned. Make sure your cross supports are positioned to minimise any sag in the middle, especially if you plan to place heavy items on the table. A crosspiece in the centre of each half span is a simple way to stiffen the frame.

Since you’re using a MIG welder but aren’t overly experienced, the key is to take your time and ensure everything is square before welding. Tack weld first at the corners to hold the frame in position, then go back and finish the welds once you’re happy with the alignment. Grinding back any sharp edges afterwards will make it safer to handle. If you prefer a simpler route, bolting the steel together using high strength bolts is an alternative that avoids welding completely, though it may change the clean “picture frame” aesthetic slightly.

For your Ekodeck boards, when slotting them into the frame, leave a small gap for expansion and contraction with changes in temperature and moisture. You can finish the tabletop flush with the steel frame, but leaving a tiny drainage gap along the edge will help prevent water pooling on the boards over time.

Finally, consider the height and leg placement carefully so there’s enough knee clearance and stability for a 10-seater. Test your leg spacing with a couple of chairs before welding the full frame if you can. With a bit of planning and patience, this should be a very achievable DIY project over a few weeks.

It’s also really important to prioritise safety when working with steel and welding. Make sure you wear appropriate PPE including a welding helmet with the correct shade, cut-resistant gloves, long sleeves, trousers, and enclosed footwear to protect against sparks and heat. Eye protection is essential even when grinding or cutting steel, and a mask or respirator is a good idea if you’re working with fumes or dust. Keeping a fire extinguisher nearby and a clear, well-ventilated workspace will help keep the project safe while you work.

Let me tag @Noyade to see if he has any thoughts.

Please let me know if you have any questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build outdoor dining furniture?

Thanks for the insight @MitchellMc . I think this might be a great opportunity to practice some welding so I'll move forward assuming that

I'm thinking that because ill be running the boards width ways along the table top that I need to have some sort of "lip" along the inside of the outter rails so that the boards have something to rest on, do you think that this is necessary? to give it enough depth ill use the outter frame with 50x50 and use 25x50mm for the two inner rails. I believe the ekodeck boards are 23mm so with some minor adjustments I believe I can achieve that "flush" look

Will 50x50 RHS tubes be strong enough to use as legs?

Also could you have a look at the attached images and see if where my proposed cross supports are in a good spot?

thanking you so far!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to build outdoor dining furniture?

I'd weld a 25 x 50mm to the side of the 50 x 50mm section @Halima. That way, you have a nice lip for the ends of the boards to sit on. I believe the 50 x 50mm will be strong enough for the legs, provided that they are attached well. Sketches look great.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.