The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Outdoor

- >

- Re: How to construct a manual lever oper...

How to make a automatic watering system?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to make a automatic watering system?

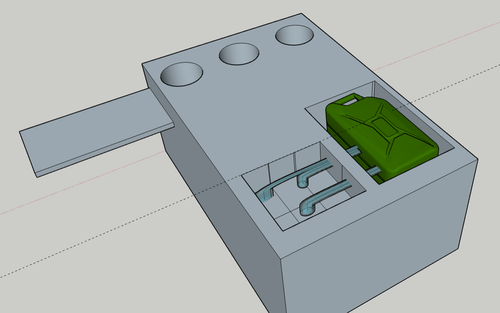

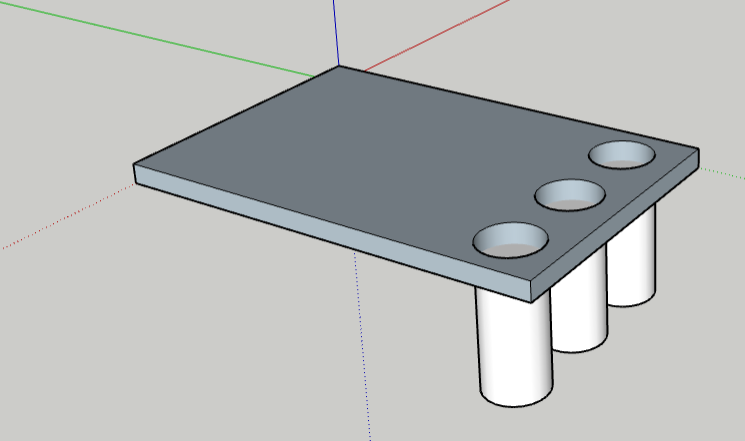

I am making a DIY project called a seedling planting system and I am stuck in this specific part of the project. The watering system. Is there a way that when a planter pulls out the lever (to the left) , somehow the water from the jerry can run through the PVC pipes and a spray nozzle connected to the end of it? Maybe some sort of switch? I don't know how to make this part of the watering system automatic...

The aim of that is to water the seedlings in the seedling container to where are the pipes are running through....

Solved! See most helpful response

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to make a automatic watering system?

If you are wanting to detect seeds dropping through then in turn trigger the water to activate and flow not matter how fast or slow then you are going to have to develop something with an Arduino for simplicity on the microcontroller / microcomputer world.

I have just run my thoughts pattern through my AI and here is the output.

Building a device to detect when seeds drop through a chute and subsequently activate a water valve via a relay is a feasible project that can be accomplished with an Arduino, a sonic sensor for seed detection, and an optocoupler relay to control the water valve. Here is a high-level overview of how you could approach this project, including the components you might use:

### Components Needed:

1. **Arduino Uno or similar**: Acts as the brain of the operation, processing the input from the sonic sensor and controlling the relay.

2. **Ultrasonic Sensor (e.g., HC-SR04)**: This sensor can detect the presence of seeds as they pass through the chute. It works by emitting an ultrasonic pulse and measuring the time it takes for the echo to return.

3. **Optocoupler Relay Module**: This is used to safely switch the water valve on and off without exposing the Arduino to the high currents involved.

4. **Solenoid Water Valve**: This valve will control the flow of water. Ensure it operates at a voltage and current that the optocoupler relay can handle.

5. **Power Supply**: For the Arduino, sensors, and the solenoid valve. The requirements will depend on the specifications of your solenoid valve and how many sensors and relays you are using.

6. **Cables and Connectors**: For connecting all components.

7. **Mounting Hardware**: Depending on your chute design, you may need custom mounting solutions for the ultrasonic sensor to ensure it accurately detects seeds passing by.

### Basic Steps:

1. **Design the Chute**: Ensure the chute design guides the seeds in such a way that they always pass within the detection range of the ultrasonic sensor.

2. **Connect the Ultrasonic Sensor to the Arduino**: Typically, the ultrasonic sensor has four pins: VCC, GND, Trig, and Echo. VCC goes to 5V on the Arduino, GND to GND, Trig to a digital pin (e.g., D2), and Echo to another digital pin (e.g., D3).

3. **Connect the Optocoupler Relay to the Arduino**: The relay module will have input pins that you can connect to another digital pin on the Arduino (e.g., D4) for control. Ensure the relay module is also powered appropriately, and that it is capable of handling the current and voltage requirements of your solenoid valve.

4. **Programming the Arduino**: Write a sketch (program) for the Arduino to monitor the ultrasonic sensor. When the sensor detects a seed, the Arduino should activate the relay for a predetermined period, opening the water valve.

5. **Test and Adjust**: Test your setup with seeds of different sizes if necessary. Adjust the sensor's positioning and the delay in the Arduino sketch as needed to ensure reliable operation.

### Example Arduino Sketch:

Below is a simple example sketch that detects an object within a certain range and activates a relay. This example assumes you have connected the Trig pin of the HC-SR04 to pin 2, the Echo pin to pin 3, and the relay to pin 4 of the Arduino.

```python

#define TRIG_PIN 2

#define ECHO_PIN 3

#define RELAY_PIN 4

void setup() {

pinMode(TRIG_PIN, OUTPUT);

pinMode(ECHO_PIN, INPUT);

pinMode(RELAY_PIN, OUTPUT);

digitalWrite(RELAY_PIN, LOW); // Start with the relay off

}

void loop() {

long duration, distance;

digitalWrite(TRIG_PIN, LOW);

delayMicroseconds(2);

digitalWrite(TRIG_PIN, HIGH);

delayMicroseconds(10);

digitalWrite(TRIG_PIN, LOW);

duration = pulseIn(ECHO_PIN, HIGH);

distance = (duration/2) / 29.1;

if (distance < 10) { // If an object is detected within 10 cm

digitalWrite(RELAY_PIN, HIGH); // Activate the relay (open the valve)

delay(1000); // Keep the valve open for 1 second

digitalWrite(RELAY_PIN, LOW); // Close the valve

}

delay(100); // Wait for 100 milliseconds before the next loop iteration

}

```

This example provides a basic starting point. You may need to adjust the detection distance, the duration the valve remains open, and other parameters based on your specific needs and the characteristics of the seeds and water flow you're working with.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to construct a manual lever operated mechanism?

Hi Team,

I am Ashriya Varri, a high school student studying in Year 12. I am looking for technical help needed for my DIY project for my HSC as it's really important. I'm making a Seedling Planting System designed for Tree Planters who suffer from physical labour and my system aims to make their manual hard work almost automatic. I'm still in the designing phase and need your help as our teacher has recommended your store! Could I please have a call back to my number or I could come into the store as I'm really in desire need for your help!

For additional information, I have a plan on how to make my system so far but not exactly on how to get started.

Below is a detailed breakdown of each step to construct a manual lever-operated mechanism for opening PVC pipes that hold seedlings and simultaneously moving the system forward:

Step 1: Design the Chassis

Objective: Build a stable frame that can support the weight of the PVC pipes full of seedlings and the additional mechanical components like the lever system.

Materials: Steel or aluminum tubing, angle brackets, screws/bolts, wheels, and tools for cutting and joining metal (e.g., welding equipment or bolt fittings).

Process:

Design Layout: Sketch out a design that can hold multiple PVC pipes (consider dimensions based on the pipe diameter and the space needed between them).

Construct Frame: Use metal tubing to create a rectangular or square frame. Ensure it is large enough to accommodate the PVC pipes and the lever mechanism but small enough for easy maneuverability.

Attach Wheels: Choose wheels suitable for your terrain. Larger, treaded wheels are better for uneven surfaces. Attach these wheels securely to the bottom corners of the frame.

Reinforce Structure: Use angle brackets at corners and joints to add stability.

Step 2: Mount the PVC Pipes

Objective: Securely attach the PVC pipes to the chassis, ensuring they can hinge open to release seedlings.

Materials: PVC pipes, metal hinges, screws, and tools for drilling.

Process:

Select and Prepare Pipes: Choose PVC pipes of appropriate diameter for your seedlings. Cut the pipes to the desired length.

Attach Hinges: Mount hinges on one end of each pipe, ensuring they align correctly so the pipes can swing open and shut smoothly. Fasten hinges to the frame.

Add Latching Mechanism: On the opposite end from the hinges, install a simple latch that will be controlled by the lever system.

Step 3: Install the Lever System

Objective: Create a lever system that the operator can use to simultaneously open all PVC pipes.

Materials: A long metal rod or pipe for the lever, linkage rods, connecting joints, and mounting brackets.

Process:

Design Lever Placement: Determine the best position for the lever for ease of use and effective transfer of motion.

Connect Lever to Latches: Use metal rods or sturdy wire to connect the lever to the latches on the PVC pipes. This might require a series of push rods, pivoting joints, or pulleys depending on the design.

Ensure Synchronous Operation: Adjust linkages so all latches release simultaneously when the lever is activated.

Step 4: Incorporate a Locking Mechanism

Objective: Ensure that the PVC pipes remain securely closed until intentionally opened via the lever.

Materials: Spring-loaded latches, small springs, bolts, and nuts.

Process:

Install Spring Mechanisms: Attach springs to the latching mechanism so they naturally pull the latch into the locked position.

Integrate with Lever: Ensure that when the lever is activated, it effectively pulls against the spring tension to open the latches.

Step 5: Setup Movement Controls

Objective: Integrate the lever not only as a mechanism to open the pipes but also to assist in moving the system forward.

Materials: Additional handle if required, linkage adjustments.

Process:

Modify Lever as Handle: Extend or adjust the lever so it can also function as a handle for pushing or pulling the cart.

Ensure Comfort and Efficiency: Adjust the height and grip of the lever/handle to make it comfortable to use while walking.

Step 6: Testing and Adjustments

Objective: Ensure all components function as intended and make necessary adjustments for optimal operation.

Materials: Seedlings, soil or other medium, possibly adjustment tools.

Process:

Load and Test: Place seedlings in the pipes, then use the lever to open them and ensure they release correctly.

Move the System: Push the system around to test the ease of movement and handle ergonomics.

Adjust As Needed: Based on testing, adjust the tension in springs, the alignment of hinges, or the setup of the lever and latches for better performance.

This detailed approach helps you create a robust system that is manually operated, cost-effective, and adaptable to various settings and seedling sizes.

Thank You,

Kind regards

Ashriya V

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to construct a manual lever operated mechanism?

Hi @ashriyavarri,

You're welcome to visit the team at your local Bunnings store for advice on your project. You can also ask your questions here so our helpful members can assist. It's best to look at your project and formulate specific questions that will aid your process, as that's the best way to overcome any challenges you might be facing.

We look forward to your questions.

Mitchell

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to construct a manual lever operated mechanism?

Hi @MitchellMc,

Could you please arrange me to a best contact person, I've tried contacting before but it was hard to find a person to ask questions to. My nearest store is Marsden Park or Rouse Hill. ![]()

Thank you.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to construct a manual lever operated mechanism?

Hi @ashriyavarri,

Feel free to ask your questions here. We have many helpful community members who love getting stuck into tricky challenges.

My advice would be to ask specific questions about specific problems. Each small problem solved will be one step closer to the fantastic system you are envisioning.

All the best with your project.

Jacob

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to construct a manual lever operated mechanism?

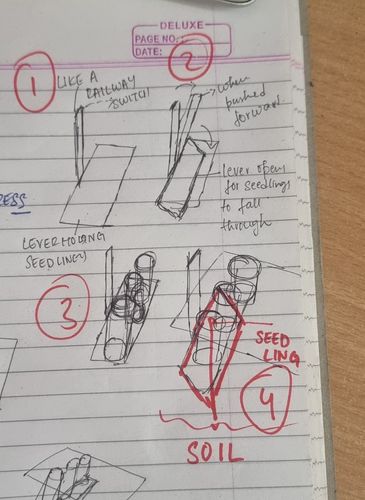

How to make a manual lever-operated system like a railway switch?

According to the below picture, as said above, I want to make a lever mechanism that opens way for the seedlings to fall through the PVC pipes and into the soil. I want the lever to work like a railway switch which is about the waist height of a person, so when the person pushes the lever forward (shown in #2), it opens the lever that is hinged at the end of the PVC pipes to open and when retracted back, the lever hinged is closed. (shown in #3) Is there anyway I can make this work in real life as I'm not sure where to begin with? The PVC pipes will be held on to the timber sheet and the lever that's about waist height is connected to the entire system that moves this system forward as well as when pushed front and back again, it opens way for seedlings. (Apologies for the bad drawing, came up with this idea on the spot)

Thank you for your generous help!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to construct a manual lever operated mechanism?

Hi @ashriyavarri,

Let me tag some clever members like @Noyade and @Dave-1 to see how they would approach it.

Jason

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

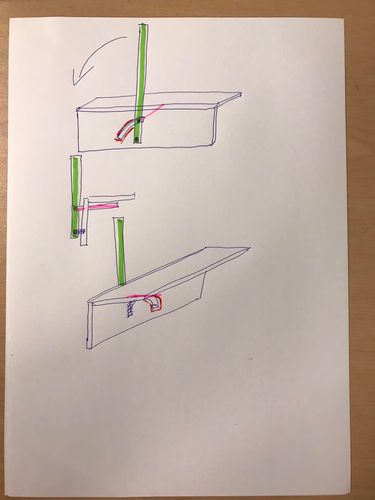

Re: How to construct a manual lever operated mechanism?

Good Morning @ashriyavarri

I think I understand what you are after. This mechanisim could have some "V" shapped pieces of timber to channel the seeds to the PV pipes below when opened they would slide down tothe V point.

The green is the handle and is fixed at one point at the base so it can pivot.

The Pink is a metal pin or thick dowel

The red outline is an arc cut in the timber side.

When the level is pushe forwards the pin would travel the arc on the way down, lowering the hinged lid.

The arc may not be a true coffee cup arc (I am not sure so you may need to experiment with the idea) so the curve may need to be wider then the pin.

Dave

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to construct a manual lever operated mechanism?

Morning @ashriyavarri (School holidays at the moment?)

Do you have an overall diagram - of the entire unit you propose? There's mention of wheels and levers.

To me, if you want to minimise labour inducing actions for the employee pushing(?) this thing, the last thing he would want to do is push and pull a lever every time we wanna drop seeds?

Is there a way of synchronizing the rotation of the wheels with the dropping of seed and water - all in one action?

So all he (or she) has to do is aim the cart(?) and push?

How are you dropping the precise amount of seed from those PVC pipes?

Just coffee thoughts. Keep us informed.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: How to construct a manual lever operated mechanism?

Hi @Noyade,

Since I am just starting, I haven't yet focused on making the system work on wheels as that's my last priority. I am currently focusing on planting, drilling and watering mechanism through this Seedling Planting System. Not to mention, I had well thought about that idea before (seeds through a wheel, as it was one of the existing solutions out there), however, it was too hard to make an automatic system all by myself at the very start. Synchronising wheels with seeds is not a problem, however, these are seedlings and not seeds so it was harder to come up with an idea that could possibly do that. I believe, with your help maybe I can get to something automatic. Your help would be greatly appreciated.!!

Thank you.

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.