The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- Discussion

- >

- Garage and Shed

- >

- Re: Shifting wooden panel mounted by met...

How to shift wooden panel mounted by metal bracket?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

How to shift wooden panel mounted by metal bracket?

I'd like to modify this digital piano stand, as the pedals are too close for my long legs. 🙃

My plan is to move the panel that the pedal unit is attached to backwards by installing additional metal brackets to each side of the stand that extend behind the back of it, and then attaching the existing bracket to that somehow. The bracket holes are ~6cm apart if it matters. I'd also like to keep it looking nice with e.g. black brackets and bolts.

It would be even better if the bracket was "adjustable", so that I could make small adjustments to the panel's position to find the ideal position, but I'll settle for what I can get. This might also cause the panel to move backwards over time if not held in place securely enough...

I'm wondering if anyone has a better solution for this, or if not, suggestions for which parts I should buy.

Thanks!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Shifting wooden panel mounted by metal bracket

After posting this, I realised the question is more or less ready to be thrown at AI, so I asked Gemini. I'm curious what people think about this:

---

Given your goal of moving the digital piano pedal panel backward to accommodate longer legs, and your preference for an adjustable and aesthetically pleasing solution, let's explore your proposed idea and some alternatives, along with specific Bunnings recommendations.

First, let's look at your plan:

Your Proposed Plan: Extending with Metal Brackets

Your idea of using additional metal brackets to extend the pedal panel backward is sound. It's a direct approach to gaining the desired legroom.

Pros:

-

Direct Solution: Directly addresses the problem of pedal proximity.

-

Relatively Simple: The concept is straightforward to implement.

-

Customizable: You can choose the exact extension length.

Challenges to Consider:

-

Stability: Ensuring the new brackets provide sufficient rigidity for the pedal unit, especially during use. You don't want the pedal unit to wobble.

-

Load Bearing: The pedal unit, while not extremely heavy, will still exert some force. The new brackets need to be strong enough.

-

Aesthetics: Finding black brackets and bolts that integrate well with the existing stand's appearance.

-

Adjustability: Achieving adjustability might require more complex bracket designs or a rail system.

Alternative Solutions (and why they might be less ideal for this specific case):

-

Modifying the Bench: While you didn't ask about this, sometimes a different bench height or depth can help. However, this doesn't directly address the pedal position relative to the stand.

-

Professional Fabrication: Having custom brackets fabricated would be ideal for strength and aesthetics, but it's significantly more expensive and time-consuming than a DIY solution from Bunnings.

-

Extending the Pedal Cables/Wires: This is an option if you were to completely detach the pedal unit, but it's not what you're asking for, and would likely result in an unstable pedal unit.

Detailed Plan & Bunnings Recommendations:

Given your preference for adjustability and a clean look, I suggest a combination of slotted angle brackets or slotted channel for adjustability, along with strong L-brackets.

Option 1: Slotted Angle or Slotted Channel (for adjustability)

This option gives you the adjustability you desire.

Parts to buy from Bunnings:

-

Slotted Angle or Slotted Channel (Black if available, or paintable):

-

Description: These are metal strips with a series of pre-drilled slots or holes, typically used for shelving or framing. The slots allow for variable bolt positions, providing adjustability. Look for a robust gauge that won't flex easily.

-

Why: The slots will be key to your "adjustable" requirement. You can bolt the existing pedal bracket to different points along the slotted angle to fine-tune the depth.

-

Examples: Look for "slotted angle steel" or "slotted channel" in the hardware or shelving section. Often, they come in galvanised steel, which you could paint black with a good quality metal spray paint (e.g., Rust-Oleum or Dulux Metalshield).

-

Quantity: You'll need two pieces, one for each side of the stand, long enough to extend from the existing attachment point backward by your desired distance, plus some overlap for mounting to the stand.

-

-

Heavy Duty L-Brackets (Black or Paintable):

-

Description: You'll need strong L-brackets to attach the slotted angle/channel to the existing stand structure. Choose a size that provides good surface area for attachment.

-

Why: These will provide the primary structural connection between your new extension and the stand.

-

Examples: Look in the brackets section. Search for "heavy duty angle bracket" or "corner brace."

-

-

Hex Head Bolts, Nuts, and Washers (Black or Paintable):

-

Description: You'll need various sizes.

-

To attach the new L-brackets to the stand.

-

To attach the slotted angle/channel to the L-brackets.

-

To attach the existing pedal bracket to the slotted angle/channel.

-

-

Why: Strong fasteners are crucial for stability. Use washers under both the bolt head and the nut to distribute the load and prevent damage to the material. Consider using Nyloc nuts (nylon insert lock nuts) or thread locker (Loctite) to prevent loosening from vibrations.

-

Examples: Look for "M6," "M8" or similar metric bolts. Measure the diameter of the holes in your existing pedal bracket and the slotted angle to ensure compatibility. If you can't find black bolts, you can paint them.

-

-

Metal Drill Bits:

-

Description: If you need to drill new holes in the stand or the new brackets (e.g., to match existing stand holes or to secure the L-brackets).

-

Why: Essential for a clean installation.

-

-

Metal Spray Paint (Black, e.g., Rust-Oleum or Dulux Metalshield):

-

Description: For painting any unpainted brackets or bolts to match the stand.

-

Why: To maintain a consistent aesthetic.

-

Installation Steps (General):

-

Measure: Carefully measure how far back you want the pedal unit to go. Also, measure the existing bolt spacing on the pedal bracket (~6cm as you mentioned).

-

Disassemble: Carefully remove the pedal panel from the stand.

-

Mount L-Brackets: Attach the heavy-duty L-brackets to the inside of the piano stand's side panels, where the existing pedal unit attached, but positioned to allow for your backward extension. Ensure they are level and secure. Use appropriate bolts, nuts, and washers. You might need to drill new holes in the stand's side panels if existing ones don't align.

-

Attach Slotted Angle/Channel: Bolt your chosen slotted angle or channel to the L-brackets. The angle should extend backward. This is where you'll utilize the slots for future adjustability.

-

Mount Pedal Panel: Attach the existing pedal bracket to the slots in your new slotted angle/channel. Use bolts, nuts, and washers. This is where you can make small adjustments to the depth of the pedal panel.

-

Test and Refine: Reassemble the pedal unit and test the position. Make small adjustments to the pedal panel's depth using the slots in the angle/channel until you find the ideal position.

-

Paint (Optional but Recommended): Once you're satisfied with the position and everything is secure, disassemble the new brackets and paint them black. Let them dry thoroughly before reassembling.

Option 2: Heavy Duty Flat Bar and L-Brackets (Less Adjustable, but simpler)

If adjustability is less critical than pure strength and simplicity, this option is viable. You would essentially create a fixed extension.

Parts to buy from Bunnings:

-

Heavy Duty Flat Steel Bar (Black or Paintable):

-

Description: A solid flat bar of steel.

-

Why: This will be the direct extension. You'll drill new holes in it to match the existing pedal bracket holes and your stand's mounting points.

-

Examples: Look for "flat bar steel" in various widths and thicknesses. Choose something substantial.

-

-

Heavy Duty L-Brackets (Black or Paintable):

-

Same as Option 1.

-

-

Hex Head Bolts, Nuts, and Washers (Black or Paintable):

-

Same as Option 1.

-

-

Metal Drill Bits:

-

Same as Option 1.

-

-

Metal Spray Paint (Black):

-

Same as Option 1.

-

Installation Steps (General):

-

Measure and Mark: Measure how far back you want the pedal unit to go. Mark the drilling points on the flat steel bar to match the existing pedal bracket holes and the mounting points on the stand.

-

Drill: Carefully drill the marked holes in the flat steel bar.

-

Mount L-Brackets: Attach the heavy-duty L-brackets to the inside of the piano stand's side panels.

-

Attach Flat Bar: Bolt the drilled flat steel bar to the L-brackets, extending backward.

-

Mount Pedal Panel: Attach the existing pedal bracket to the drilled holes in the flat steel bar.

-

Test and Paint: Test the position and stability. Disassemble and paint if desired, then reassemble.

Important Considerations for Both Options:

-

Tools: You'll likely need a drill, drill bits (for metal), a wrench/spanner set, a measuring tape, a marker, and potentially clamps to hold pieces while drilling.

-

Safety: Wear safety glasses when drilling.

-

Measure Twice, Cut/Drill Once: Precision in your measurements will save you headaches.

-

Test Fit: Before making any permanent modifications or painting, dry-fit all the components to ensure they align and function as intended.

-

Cable Management: Consider how the existing power/signal cable for the pedal unit will be routed with the new position. You might need to use cable ties to keep it tidy.

-

Aesthetics: If you can't find pre-blackened parts, a good quality metal spray paint designed for outdoor use will provide a durable and aesthetically pleasing finish. Remember to prime the metal first for best adhesion.

I lean towards Option 1 (Slotted Angle/Channel) because it directly addresses your desire for adjustability, which will be valuable in finding that "ideal position" for your long legs. Good luck with your modification!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Shifting wooden panel mounted by metal bracket

This could be good for making it adjustable:

https://www.bunnings.com.au/metal-mate-32-x-32-x-1-5mm-0-6m-slotted-black-angle_p1138238

Although the stand is only ~26cm deep, so at 60cm it's too long and I'd need to cut it. I do have an angle grinder, but not sure what disc I'd need for cutting this? I currently only have this masonry disc:

Would this saw work? I bought it for cutting PVC, but it looks like the one shown in the product images.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Shifting wooden panel mounted by metal bracket

After thinking about this some more, the pedal unit was already sitting on the ground when it was attached to the stand, so I could do this in a much easier and more flexible way if I found an L bracket that could go on each end of the panel (attaching to the existing mounts), and then put rubber feet on the bottom of the bracket that sits on the ground. The only issues are then finding a bracket that will have it sit at the right height, and potentially also the panel not being heavy enough so that it moves back when I apply pressure with my foot...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Shifting wooden panel mounted by metal bracket

Hello @ALimestoneWall

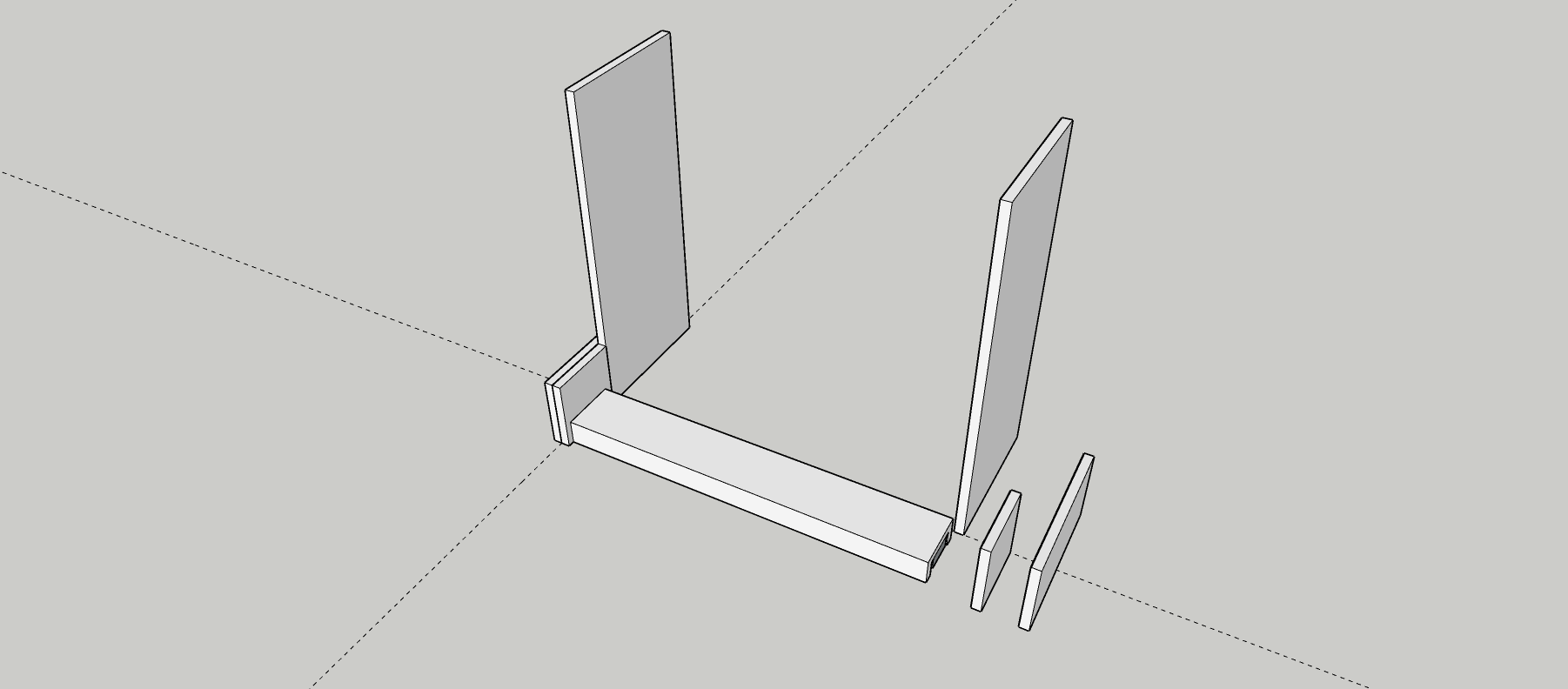

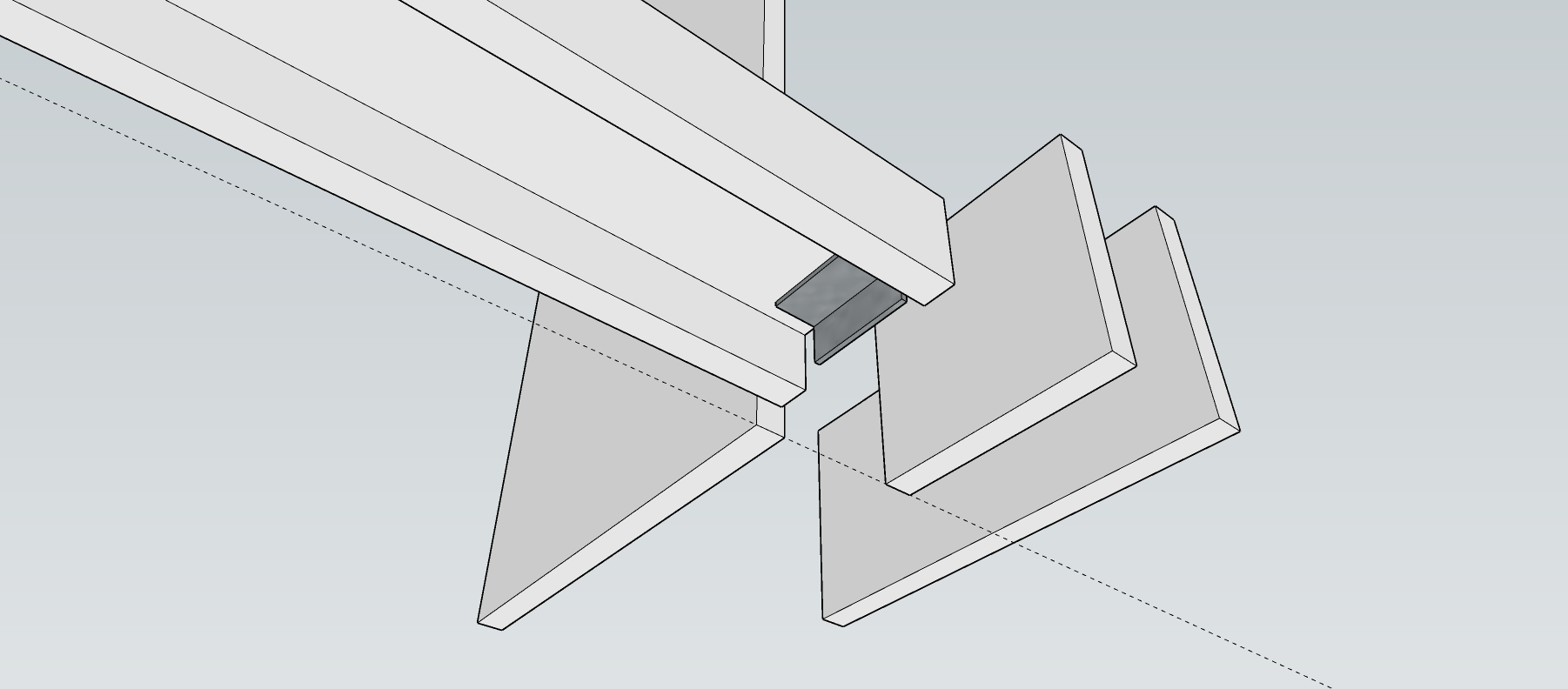

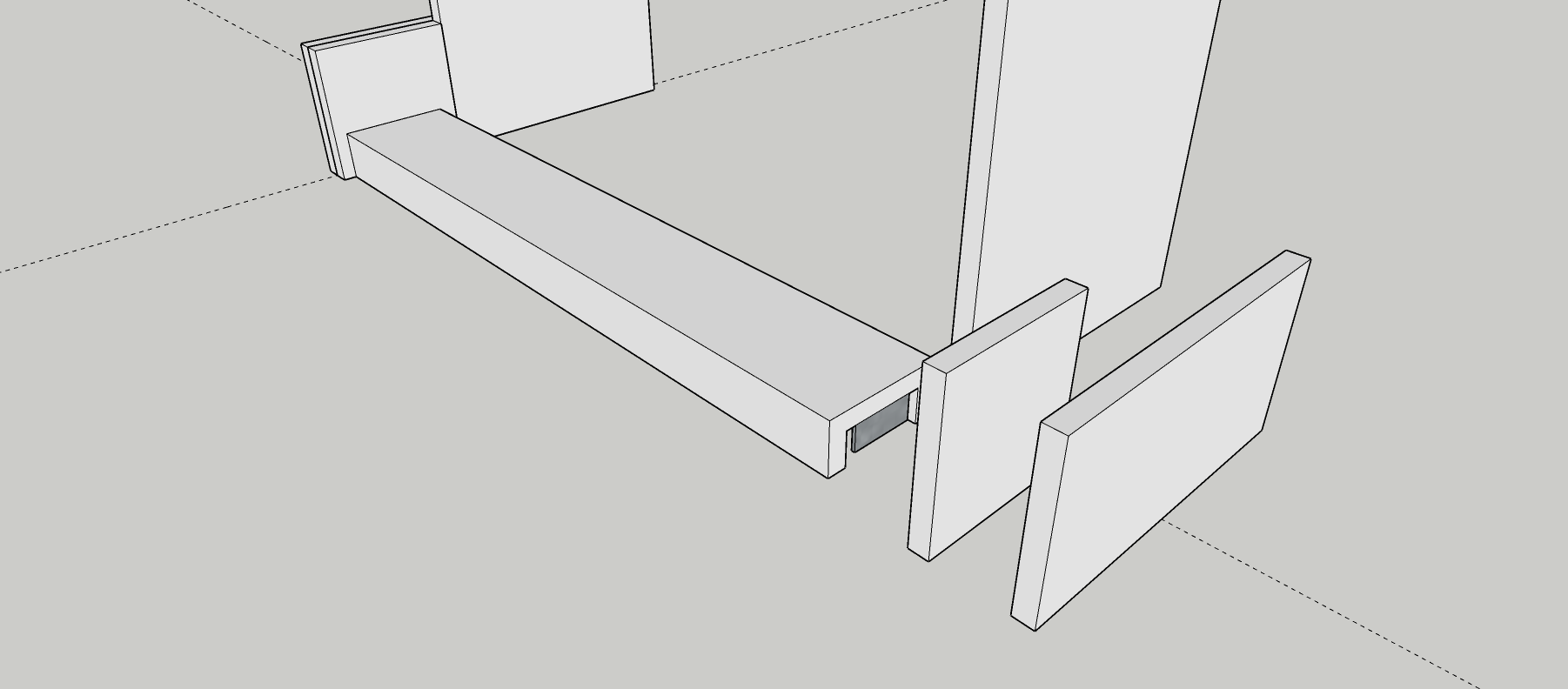

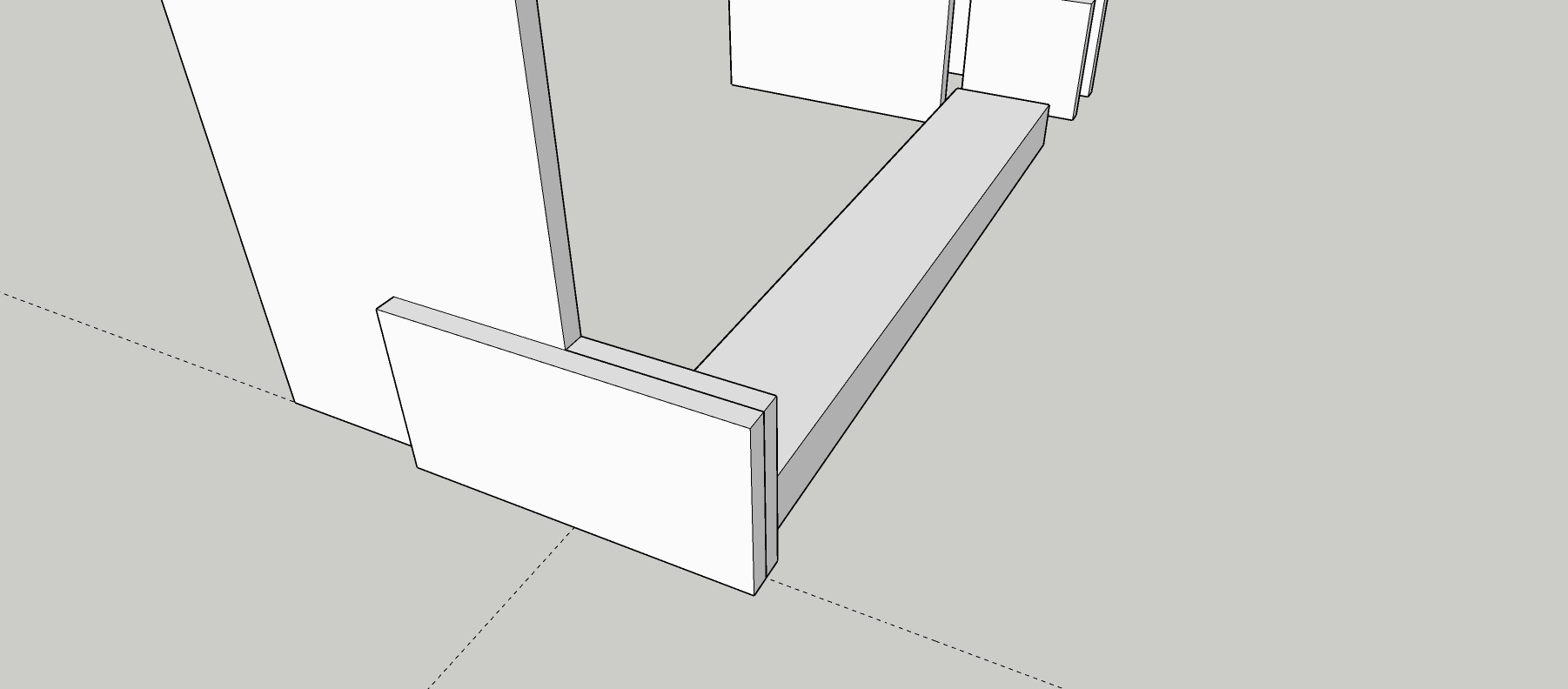

Thanks for sharing your question about your moving the pedal unit of your digital piano. I propose adding two timber pieces to create an extension that will allow you to move the entire pedal structure to the position that you're comfortable with. I've drawn up a quick sketch and placed it at the bottom, please have a look and tell me what you think. I suggest using pine or MDF as extension pieces and screwing it in place using Zenith 8G x 28mm Gold Passivated Countersunk Rib Head Chipboard Screws - 38 Pack on the condition that you'll be using 18mm thick timber pieces.

Please adjust your screw length to the thickness of the timber piece you'll be using. The screws I've indicated are for example only.

If you have any other questions we can help with, please let us know.

Eric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Shifting wooden panel mounted by metal bracket

Thanks Eric, I somehow missed this response.

I ended up buying a pedal unit that sits on the floor, as it is a more flexible solution.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Highlight

- Report Inappropriate Content

Re: Shifting wooden panel mounted by metal bracket

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.